Alloy Steel Bar: A Strategic Investment for Industrial Applications

In modern engineering and manufacturing, material performance is as critical as design. Industries today demand strength, durability, and precision from every component, and one material that consistently delivers across sectors is the alloy steel bar. Recognized for its enhanced mechanical properties and versatility, this steel variant plays a pivotal role in heavy-duty manufacturing, automotive engineering, power generation, and infrastructure development.

________________________________________

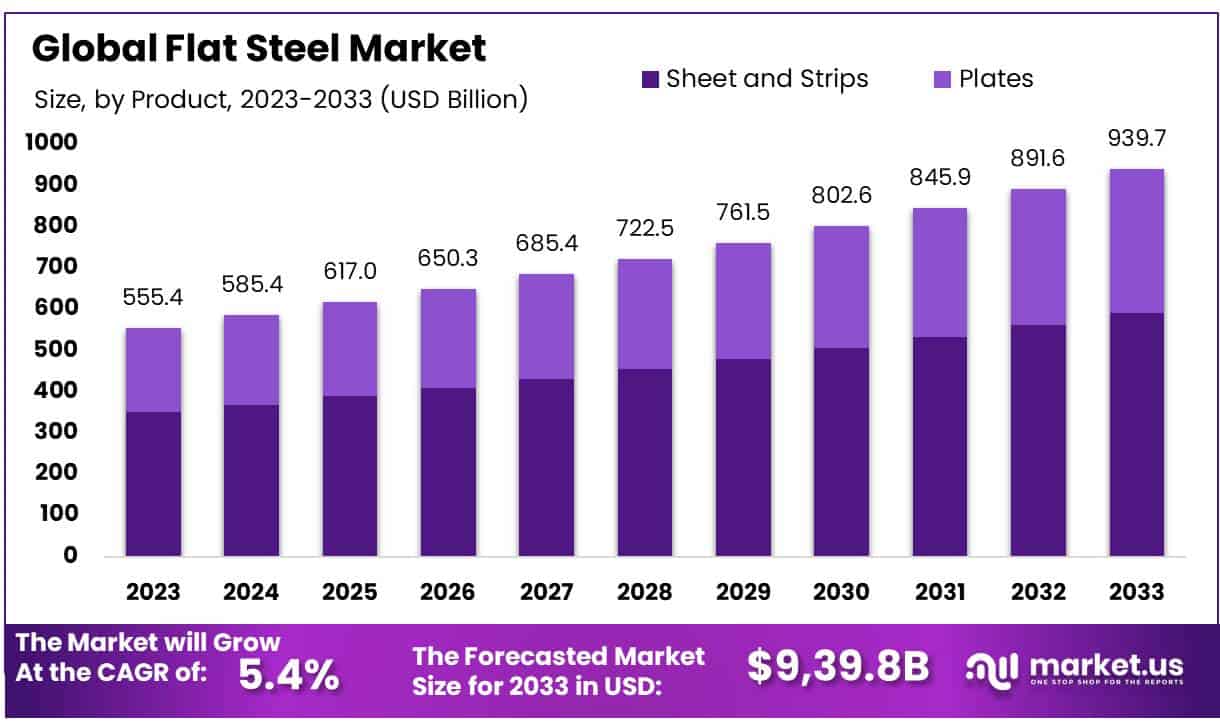

Market Demand for MS Square Bar and Alloy Steel Products

While mild steel (MS) square bars remain widely used in general fabrication, there’s an increasing demand. The shift is driven by rising expectations around material performance, especially in environments subject to heat, pressure, and wear.

Why Alloy Steel is Gaining Ground

• Higher Strength-to-Weight Ratio: Alloying elements such as chromium, molybdenum, and nickel improve tensile strength without excessive weight.

• Enhanced Wear and Corrosion Resistance: Ideal for critical applications in mining, *** & gas, and automotive manufacturing.

• Adaptability for Heat Treatment: Can be heat-treated to achieve specific hardness or toughness levels, offering design flexibility.

• Global Infrastructure Boom: As infrastructure projects expand globally, demand for premium-grade materials like alloy steel continues to grow.

In comparison, MS square bars are still widely preferred for basic construction and general-purpose fabrication, but when performance and longevity are the priority, the industry increasingly turns to alloy steel solutions.

________________________________________

Supplier / Manufacturer Selection Tips

1. Verify Metallurgical Standards

Ensure that the steel alloy bars comply with global standards such as ASTM A182, AISI, SAE, or DIN. Suppliers should provide complete chemical and mechanical test reports, ensuring traceability.

2. Understand the Grade Offerings

Not all steel alloy bars are created equal. Common grades include EN19, EN24, 42CrMo4, and 4140—all offering unique performance profiles. Choose manufacturers who provide grade-specific customization.

3. Evaluate Processing Capabilities

High-end applications often require precise tolerances, controlled heat treatment, and specific surface finishes. Assess whether the supplier has integrated facilities for forging, machining, and testing.

4. Consider Delivery and Export Efficiency

Bulk buyers and global exporters should work with suppliers who offer reliable lead times, export packaging, and logistics support, including documentation like MTCs, inspection reports, and third-party certifications.

5. Review Industry Experience and Client Portfolio

Look for manufacturers and suppliers with a proven track record across industries such as automotive, defense, heavy machinery, and *** & gas. Client testimonials, case studies, or certifications like ISO 9001 add to their credibility.

________________________________________

Alloy steel bar are used in high-load and high-impact applications, where standard steel fails to perform. Common applications include:

• Automotive: Crankshafts, gears, drive axles, and suspension parts

• Aerospace: Structural components requiring high fatigue resistance

• *** & Gas: Drilling tools, valves, and pressure control equipment

• Power Plants: Turbine shafts, fasteners, and structural supports

• General Engineering: Machine parts, tooling equipment, and dies

Due to their versatility, these bars are essential to projects where safety, performance, and durability cannot be compromised.

________________________________________

Frequently Asked Questions (FAQs)

1. What is the difference between alloy steel and carbon steel bars?

Alloy steel contains additional elements like chromium or molybdenum, which enhance mechanical properties beyond what standard carbon steel can offer.

2. Can alloy steel bars be customized to size?

Yes. Reputed manufacturers offer custom dimensions, heat treatments, and surface finishes tailored to client specifications.

3. Are alloy steel bars suitable for welding?

It depends on the grade. Some alloy steels require preheating or post-weld heat treatment to maintain strength and avoid cracking.

4. What certifications should I ask for when sourcing alloy steel bars?

Look for MTCs (Material Test Certificates), third-party inspection reports, and compliance with international standards like ASTM, SAE, or EN.

5. What factors affect the cost of alloy steel bars?

Grade composition, size, finish, processing (forging, heat treatment), and global commodity pricing all influence the final cost.

Visit :- https://www.mayoworld.com/suppliers/alloy-steel-bar

#Alloy Steel 4140 Round Bar #Alloy Steel Bars Manufacturers #Alloy Steel Bar Manufacturers & Suppliers

In modern engineering and manufacturing, material performance is as critical as design. Industries today demand strength, durability, and precision from every component, and one material that consistently delivers across sectors is the alloy steel bar. Recognized for its enhanced mechanical properties and versatility, this steel variant plays a pivotal role in heavy-duty manufacturing, automotive engineering, power generation, and infrastructure development.

________________________________________

Market Demand for MS Square Bar and Alloy Steel Products

While mild steel (MS) square bars remain widely used in general fabrication, there’s an increasing demand. The shift is driven by rising expectations around material performance, especially in environments subject to heat, pressure, and wear.

Why Alloy Steel is Gaining Ground

• Higher Strength-to-Weight Ratio: Alloying elements such as chromium, molybdenum, and nickel improve tensile strength without excessive weight.

• Enhanced Wear and Corrosion Resistance: Ideal for critical applications in mining, *** & gas, and automotive manufacturing.

• Adaptability for Heat Treatment: Can be heat-treated to achieve specific hardness or toughness levels, offering design flexibility.

• Global Infrastructure Boom: As infrastructure projects expand globally, demand for premium-grade materials like alloy steel continues to grow.

In comparison, MS square bars are still widely preferred for basic construction and general-purpose fabrication, but when performance and longevity are the priority, the industry increasingly turns to alloy steel solutions.

________________________________________

Supplier / Manufacturer Selection Tips

1. Verify Metallurgical Standards

Ensure that the steel alloy bars comply with global standards such as ASTM A182, AISI, SAE, or DIN. Suppliers should provide complete chemical and mechanical test reports, ensuring traceability.

2. Understand the Grade Offerings

Not all steel alloy bars are created equal. Common grades include EN19, EN24, 42CrMo4, and 4140—all offering unique performance profiles. Choose manufacturers who provide grade-specific customization.

3. Evaluate Processing Capabilities

High-end applications often require precise tolerances, controlled heat treatment, and specific surface finishes. Assess whether the supplier has integrated facilities for forging, machining, and testing.

4. Consider Delivery and Export Efficiency

Bulk buyers and global exporters should work with suppliers who offer reliable lead times, export packaging, and logistics support, including documentation like MTCs, inspection reports, and third-party certifications.

5. Review Industry Experience and Client Portfolio

Look for manufacturers and suppliers with a proven track record across industries such as automotive, defense, heavy machinery, and *** & gas. Client testimonials, case studies, or certifications like ISO 9001 add to their credibility.

________________________________________

Alloy steel bar are used in high-load and high-impact applications, where standard steel fails to perform. Common applications include:

• Automotive: Crankshafts, gears, drive axles, and suspension parts

• Aerospace: Structural components requiring high fatigue resistance

• *** & Gas: Drilling tools, valves, and pressure control equipment

• Power Plants: Turbine shafts, fasteners, and structural supports

• General Engineering: Machine parts, tooling equipment, and dies

Due to their versatility, these bars are essential to projects where safety, performance, and durability cannot be compromised.

________________________________________

Frequently Asked Questions (FAQs)

1. What is the difference between alloy steel and carbon steel bars?

Alloy steel contains additional elements like chromium or molybdenum, which enhance mechanical properties beyond what standard carbon steel can offer.

2. Can alloy steel bars be customized to size?

Yes. Reputed manufacturers offer custom dimensions, heat treatments, and surface finishes tailored to client specifications.

3. Are alloy steel bars suitable for welding?

It depends on the grade. Some alloy steels require preheating or post-weld heat treatment to maintain strength and avoid cracking.

4. What certifications should I ask for when sourcing alloy steel bars?

Look for MTCs (Material Test Certificates), third-party inspection reports, and compliance with international standards like ASTM, SAE, or EN.

5. What factors affect the cost of alloy steel bars?

Grade composition, size, finish, processing (forging, heat treatment), and global commodity pricing all influence the final cost.

Visit :- https://www.mayoworld.com/suppliers/alloy-steel-bar

#Alloy Steel 4140 Round Bar #Alloy Steel Bars Manufacturers #Alloy Steel Bar Manufacturers & Suppliers

Alloy Steel Bar: A Strategic Investment for Industrial Applications

In modern engineering and manufacturing, material performance is as critical as design. Industries today demand strength, durability, and precision from every component, and one material that consistently delivers across sectors is the alloy steel bar. Recognized for its enhanced mechanical properties and versatility, this steel variant plays a pivotal role in heavy-duty manufacturing, automotive engineering, power generation, and infrastructure development.

________________________________________

Market Demand for MS Square Bar and Alloy Steel Products

While mild steel (MS) square bars remain widely used in general fabrication, there’s an increasing demand. The shift is driven by rising expectations around material performance, especially in environments subject to heat, pressure, and wear.

Why Alloy Steel is Gaining Ground

• Higher Strength-to-Weight Ratio: Alloying elements such as chromium, molybdenum, and nickel improve tensile strength without excessive weight.

• Enhanced Wear and Corrosion Resistance: Ideal for critical applications in mining, oil & gas, and automotive manufacturing.

• Adaptability for Heat Treatment: Can be heat-treated to achieve specific hardness or toughness levels, offering design flexibility.

• Global Infrastructure Boom: As infrastructure projects expand globally, demand for premium-grade materials like alloy steel continues to grow.

In comparison, MS square bars are still widely preferred for basic construction and general-purpose fabrication, but when performance and longevity are the priority, the industry increasingly turns to alloy steel solutions.

________________________________________

Supplier / Manufacturer Selection Tips

1. Verify Metallurgical Standards

Ensure that the steel alloy bars comply with global standards such as ASTM A182, AISI, SAE, or DIN. Suppliers should provide complete chemical and mechanical test reports, ensuring traceability.

2. Understand the Grade Offerings

Not all steel alloy bars are created equal. Common grades include EN19, EN24, 42CrMo4, and 4140—all offering unique performance profiles. Choose manufacturers who provide grade-specific customization.

3. Evaluate Processing Capabilities

High-end applications often require precise tolerances, controlled heat treatment, and specific surface finishes. Assess whether the supplier has integrated facilities for forging, machining, and testing.

4. Consider Delivery and Export Efficiency

Bulk buyers and global exporters should work with suppliers who offer reliable lead times, export packaging, and logistics support, including documentation like MTCs, inspection reports, and third-party certifications.

5. Review Industry Experience and Client Portfolio

Look for manufacturers and suppliers with a proven track record across industries such as automotive, defense, heavy machinery, and oil & gas. Client testimonials, case studies, or certifications like ISO 9001 add to their credibility.

________________________________________

Alloy steel bar are used in high-load and high-impact applications, where standard steel fails to perform. Common applications include:

• Automotive: Crankshafts, gears, drive axles, and suspension parts

• Aerospace: Structural components requiring high fatigue resistance

• Oil & Gas: Drilling tools, valves, and pressure control equipment

• Power Plants: Turbine shafts, fasteners, and structural supports

• General Engineering: Machine parts, tooling equipment, and dies

Due to their versatility, these bars are essential to projects where safety, performance, and durability cannot be compromised.

________________________________________

Frequently Asked Questions (FAQs)

1. What is the difference between alloy steel and carbon steel bars?

Alloy steel contains additional elements like chromium or molybdenum, which enhance mechanical properties beyond what standard carbon steel can offer.

2. Can alloy steel bars be customized to size?

Yes. Reputed manufacturers offer custom dimensions, heat treatments, and surface finishes tailored to client specifications.

3. Are alloy steel bars suitable for welding?

It depends on the grade. Some alloy steels require preheating or post-weld heat treatment to maintain strength and avoid cracking.

4. What certifications should I ask for when sourcing alloy steel bars?

Look for MTCs (Material Test Certificates), third-party inspection reports, and compliance with international standards like ASTM, SAE, or EN.

5. What factors affect the cost of alloy steel bars?

Grade composition, size, finish, processing (forging, heat treatment), and global commodity pricing all influence the final cost.

Visit :- https://www.mayoworld.com/suppliers/alloy-steel-bar

#Alloy Steel 4140 Round Bar #Alloy Steel Bars Manufacturers #Alloy Steel Bar Manufacturers & Suppliers

0 Yorumlar

·0 hisse senetleri

·71 Views

·0 önizleme