Sponsored

@excellenthydraulicworks

Hi, my name is Abdullah Siddiqui. I work at Excellent Hydraulic Works- hydraulic repair shop in Delhi offering expert hydraulic pump and motor repair services for all famous brands like danfoss, rexorth, parker , nachi and many more with over 27 years of trusted industry experience.

21 Posts

20 Photos

0 Videos

Recent Updates

-

How Do We Restore Worn Hydraulic Pumps to Peak Performance?

Have a look at before and after pics of hydraulic components- Which was once a tired and worn hydraulic pump part is now restored to peak performance, ready to take on demanding tasks.

A malfunctioning hydraulic pump can cause costly downtime and disrupt your workflow. At Excellent Hydraulic Works, we understand how crucial efficient equipment is to your operations. The before image reflects the struggles of aging machinery: uneven surfaces, wear, and performance loss. The after image highlights the outcome of our meticulous work with smooth finishes, precise fitment, and restored functionality matching with OEM standards.

Our expert technicians specialize in bringing hydraulic components back to life, using advanced repair techniques and genuine parts to ensure reliability and durability.

You can Trust us for quality repairs, timely service, and technical expertise. Whether you need routine maintenance or emergency pump restoration, we are just a call away. Give your hydraulic equipment the care it deserves and let us take it from tired to ready for action.

Visit us to explore our one stop solution for Hydraulic Pump Repair of all brands http://www.hydraulicpumprepair.in

#hydraulicrepairshop #excellenthydraulicworks #hydraulicpumprepair #hydraulicpumpservice #hydraulicpumprebuild #industrialmaintance #industrialservice #pumprepairshop

How Do We Restore Worn Hydraulic Pumps to Peak Performance? Have a look at before and after pics of hydraulic components- Which was once a tired and worn hydraulic pump part is now restored to peak performance, ready to take on demanding tasks. A malfunctioning hydraulic pump can cause costly downtime and disrupt your workflow. At Excellent Hydraulic Works, we understand how crucial efficient equipment is to your operations. The before image reflects the struggles of aging machinery: uneven surfaces, wear, and performance loss. The after image highlights the outcome of our meticulous work with smooth finishes, precise fitment, and restored functionality matching with OEM standards. Our expert technicians specialize in bringing hydraulic components back to life, using advanced repair techniques and genuine parts to ensure reliability and durability. You can Trust us for quality repairs, timely service, and technical expertise. Whether you need routine maintenance or emergency pump restoration, we are just a call away. Give your hydraulic equipment the care it deserves and let us take it from tired to ready for action. Visit us to explore our one stop solution for Hydraulic Pump Repair of all brands http://www.hydraulicpumprepair.in #hydraulicrepairshop #excellenthydraulicworks #hydraulicpumprepair #hydraulicpumpservice #hydraulicpumprebuild #industrialmaintance #industrialservice #pumprepairshop0 Comments ·0 Shares ·6 Views ·0 Reviews -

What are the common issues in Kawasaki pumps and how to fix them?

Without a doubt, Kawasaki pumps are reliable. Despite being designed for demanding tasks and large machinery, they begin to show wear after many years of use. Leakage of *** is typically one of the first things people notice. The most common cause is worn-out gaskets or seals. It's only a few drops at first, nothing major, but if you let it go, the pressure decreases and the pump feels weaker.

Another headache is heat. After long working hours, the *** sometimes gets hotter than it should. Hot *** breaks down quicker, and that means less lubrication inside, which speeds up wear and tear. Then there’s the problem of dirty ***. Dust, debris, or even a bit of water in the system can scrape pistons and clog small passages.

We also see a lot of cavitation. That’s when you hear a strange rattling noise because air bubbles are forming and collapsing inside the pump. Over time, that eats away at metal parts. Low pressure, weak flow, or noisy operation usually points to worn pistons, clogged filters, or misaligned bearings.

The fix is simple: stay on top of *** changes, check for leaks, and replace weak parts on time. Want the full details? Check our blog: https://www.hydraulicpumprepair.in/blog/common-issues-in-kawasaki-pump/

#hydraylicpumprepair #hydraulicpump #kawasakipump #pumpmaintenance

#excellenthydraulicworks

What are the common issues in Kawasaki pumps and how to fix them? Without a doubt, Kawasaki pumps are reliable. Despite being designed for demanding tasks and large machinery, they begin to show wear after many years of use. Leakage of oil is typically one of the first things people notice. The most common cause is worn-out gaskets or seals. It's only a few drops at first, nothing major, but if you let it go, the pressure decreases and the pump feels weaker. Another headache is heat. After long working hours, the oil sometimes gets hotter than it should. Hot oil breaks down quicker, and that means less lubrication inside, which speeds up wear and tear. Then there’s the problem of dirty oil. Dust, debris, or even a bit of water in the system can scrape pistons and clog small passages. We also see a lot of cavitation. That’s when you hear a strange rattling noise because air bubbles are forming and collapsing inside the pump. Over time, that eats away at metal parts. Low pressure, weak flow, or noisy operation usually points to worn pistons, clogged filters, or misaligned bearings. The fix is simple: stay on top of oil changes, check for leaks, and replace weak parts on time. Want the full details? Check our blog: https://www.hydraulicpumprepair.in/blog/common-issues-in-kawasaki-pump/ #hydraylicpumprepair #hydraulicpump #kawasakipump #pumpmaintenance #excellenthydraulicworks0 Comments ·0 Shares ·6 Views ·0 Reviews -

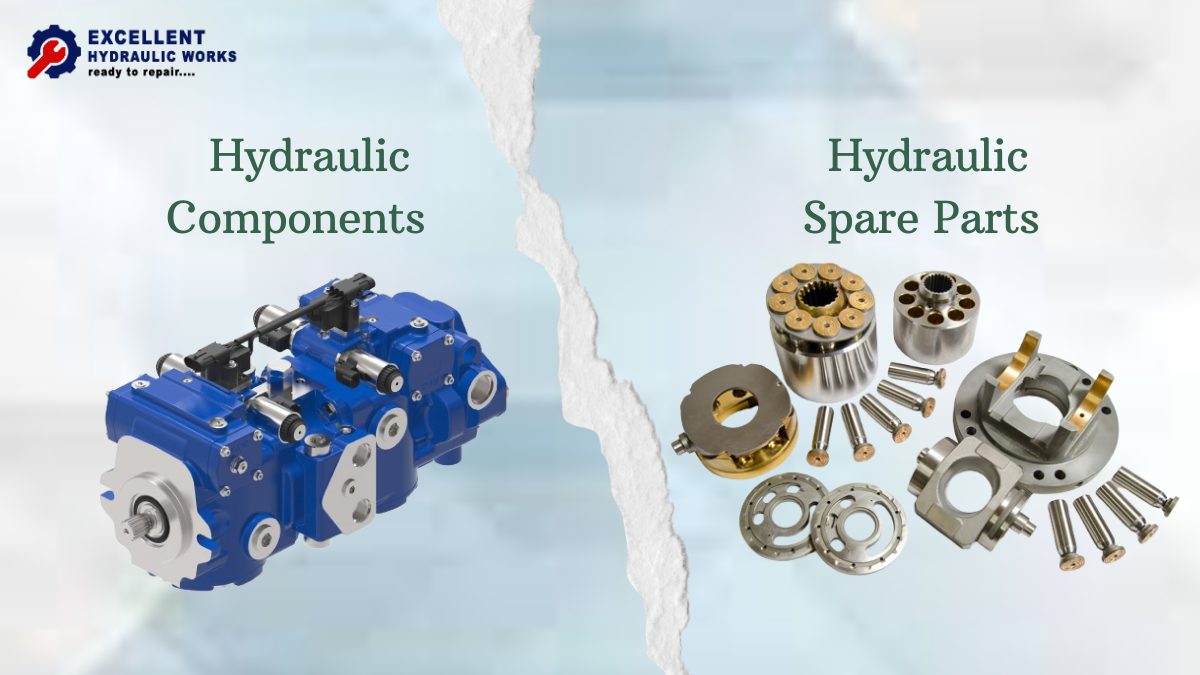

Are hydraulic components and spare parts the same?

No, hydraulic components and spare parts are correlated but are distinct in characteristics.

• Hydraulic Components: These are the essential parts that are installed in the composition of the hydraulic system and include pumps, motors, cylinders, valves, filters, hoses, reservoirs, and actuators. These are essential parts for the operability and functionality of the entire system. In case of failure of components, these can be rebuilt or replaced with OEM parts or reliable aftermarket products.

visit us- https://www.hydraulicpumprepair.in/hydraulic-component.html

• Spare Parts: These are tiny items used inside Hydraulic Cylinder Repair and consumables like seals and filters, gaskets, bearings, springs, filters, service parts (such as replacement pumps or cylinders), or interchangeable parts meant to swap out worn, damaged, or failing components. Spare parts are available at the Hydraulic repair shop to provide fast maintenance and repairs, ensuring the hydraulic system continues operating efficiently when original components wear out or break.

#hydraulicrepairshop #excellenthydraulicworks #hydraulicpumprepair #hydraulicpumpservice #hydraulicpumprebuild #industrialmaintance #industrialservice #pumprepairshop #hydrauliccylinderrepair #hydrauliccylinder

Are hydraulic components and spare parts the same? No, hydraulic components and spare parts are correlated but are distinct in characteristics. • Hydraulic Components: These are the essential parts that are installed in the composition of the hydraulic system and include pumps, motors, cylinders, valves, filters, hoses, reservoirs, and actuators. These are essential parts for the operability and functionality of the entire system. In case of failure of components, these can be rebuilt or replaced with OEM parts or reliable aftermarket products. visit us- https://www.hydraulicpumprepair.in/hydraulic-component.html • Spare Parts: These are tiny items used inside Hydraulic Cylinder Repair and consumables like seals and filters, gaskets, bearings, springs, filters, service parts (such as replacement pumps or cylinders), or interchangeable parts meant to swap out worn, damaged, or failing components. Spare parts are available at the Hydraulic repair shop to provide fast maintenance and repairs, ensuring the hydraulic system continues operating efficiently when original components wear out or break. #hydraulicrepairshop #excellenthydraulicworks #hydraulicpumprepair #hydraulicpumpservice #hydraulicpumprebuild #industrialmaintance #industrialservice #pumprepairshop #hydrauliccylinderrepair #hydrauliccylinder0 Comments ·0 Shares ·11 Views ·0 Reviews -

Should You Repair or Rebuild Your Hydraulic Cylinder?

If your hydraulic cylinder starts leaking, losing pressure, or slowing down, the big question is should you go for a repair or a complete rebuild?

A hydraulic cylinder repair is the right choice when the issue is minor, like a worn-out seal, a small leak, or light surface damage. It’s quick, affordable, and gets your machine back to work without long downtime.

However, if the cylinder is old, bent, or prone and faces recurring issues, a hydraulic cylinder rebuild service may be a more sensible option. Rebuilding means stripping the cylinder, replacing worn parts with OEM components, and restoring it to near-new condition.

read more- https://689f682e72210.site123.me/articles/repair-or-rebuild-what-is-the-smartest-choice-for-your-hydraulic-cylinder

In demanding environments like the Delhi NCR hydraulic equipment repair, repeated fixes can be more costly in the long run. A rebuild often delivers better reliability, and a technician can guide you to the smartest choice.

#hydraulicrepairshop #excellenthydraulicworks #hydraulicpumprepair #hydraulicpumpservice #hydraulicpumprebuild #industrialmaintance #industrialservice #pumprepairshop

Should You Repair or Rebuild Your Hydraulic Cylinder? If your hydraulic cylinder starts leaking, losing pressure, or slowing down, the big question is should you go for a repair or a complete rebuild? A hydraulic cylinder repair is the right choice when the issue is minor, like a worn-out seal, a small leak, or light surface damage. It’s quick, affordable, and gets your machine back to work without long downtime. However, if the cylinder is old, bent, or prone and faces recurring issues, a hydraulic cylinder rebuild service may be a more sensible option. Rebuilding means stripping the cylinder, replacing worn parts with OEM components, and restoring it to near-new condition. read more- https://689f682e72210.site123.me/articles/repair-or-rebuild-what-is-the-smartest-choice-for-your-hydraulic-cylinder In demanding environments like the Delhi NCR hydraulic equipment repair, repeated fixes can be more costly in the long run. A rebuild often delivers better reliability, and a technician can guide you to the smartest choice. #hydraulicrepairshop #excellenthydraulicworks #hydraulicpumprepair #hydraulicpumpservice #hydraulicpumprebuild #industrialmaintance #industrialservice #pumprepairshop0 Comments ·0 Shares ·11 Views ·0 Reviews -

How to Choose a Reliable Hydraulic Pump Repair Service Provider?

When your hydraulic pump starts facing issues, the last thing you want is to hand it over to the wrong repair shop. A poor fix today can turn into another breakdown tomorrow. That’s why choosing the right service provider matters.

First, look for people who’ve been around the block with your pump type gear, piston, vane, whatever you’ve got. Experience makes a huge difference. I’ve seen cases where a seasoned tech spotted the issue in minutes, while a newbie kept guessing for hours.

Next, they shouldn’t just jump in with a wrench. A proper check, testing pressure, running it under load, and listening for odd sounds can save a lot of time and money.

Reputation? Don’t just Google reviews. Ask a friend in the industry who they trust. You’ll learn more from one real conversation than ten online ratings.

If they can come to your site, even better, less downtime, less hassle. And please, avoid shops that use cheap parts. I have learned that lesson the hard way to choose a Reliable Hydraulic Pump Repair Service Provider.

read more - https://hydraulicpumprepairing.wordpress.com/2025/08/12/how-to-choose-a-reliable-hydraulic-pump-repair-service-provider/

Finally, good ones don’t vanish after you pay. They’ll give you tips, warranties, and answer the phone if trouble returns.

#hydraulicpumprepair #excellenthydraulicworks #hydraulicpump #pumprepairshop #hydraulicpumpservices #industrialmaintance #industrialservices

How to Choose a Reliable Hydraulic Pump Repair Service Provider? When your hydraulic pump starts facing issues, the last thing you want is to hand it over to the wrong repair shop. A poor fix today can turn into another breakdown tomorrow. That’s why choosing the right service provider matters. First, look for people who’ve been around the block with your pump type gear, piston, vane, whatever you’ve got. Experience makes a huge difference. I’ve seen cases where a seasoned tech spotted the issue in minutes, while a newbie kept guessing for hours. Next, they shouldn’t just jump in with a wrench. A proper check, testing pressure, running it under load, and listening for odd sounds can save a lot of time and money. Reputation? Don’t just Google reviews. Ask a friend in the industry who they trust. You’ll learn more from one real conversation than ten online ratings. If they can come to your site, even better, less downtime, less hassle. And please, avoid shops that use cheap parts. I have learned that lesson the hard way to choose a Reliable Hydraulic Pump Repair Service Provider. read more - https://hydraulicpumprepairing.wordpress.com/2025/08/12/how-to-choose-a-reliable-hydraulic-pump-repair-service-provider/ Finally, good ones don’t vanish after you pay. They’ll give you tips, warranties, and answer the phone if trouble returns. #hydraulicpumprepair #excellenthydraulicworks #hydraulicpump #pumprepairshop #hydraulicpumpservices #industrialmaintance #industrialservices0 Comments ·0 Shares ·35 Views ·0 Reviews -

How Can Regular Diagnostics Prevent Hydraulic Pump Breakdowns?

Hydraulic pump failures don't fail suddenly; they creep up on you. Maybe you have noticed the pressure isn’t quite where it should be, the ***’s running hotter than normal, or the pump’s making a sound you’ve never heard before. Those little things are the machine’s way of telling you something’s wrong.

Regular diagnostics is how we listen to those signals. We check pressure, temperature, flow, and even those split-second pressure spikes most people miss. These numbers tell us if the pump’s wearing out inside, if there’s a leak starting, or if the cooling system’s struggling.

Fixing a small issue early is quicker, cheaper, and far less stressful than dealing with a full breakdown. A simple check today can save you days of downtime tomorrow.

Keep operations smooth, reduce downtime, and save on costly repairs with our expert Hydraulic Pump Repair Services.

Contact us today to schedule a performance check or urgent repair- https://www.hydraulicpumprepair.in/

#hydraulicpumprepair #excellenthydraulicworks #hydraulicpump #pumprepairshop #hydraulicpumpservices #industrialmaintance #industrialservices

How Can Regular Diagnostics Prevent Hydraulic Pump Breakdowns? Hydraulic pump failures don't fail suddenly; they creep up on you. Maybe you have noticed the pressure isn’t quite where it should be, the oil’s running hotter than normal, or the pump’s making a sound you’ve never heard before. Those little things are the machine’s way of telling you something’s wrong. Regular diagnostics is how we listen to those signals. We check pressure, temperature, flow, and even those split-second pressure spikes most people miss. These numbers tell us if the pump’s wearing out inside, if there’s a leak starting, or if the cooling system’s struggling. Fixing a small issue early is quicker, cheaper, and far less stressful than dealing with a full breakdown. A simple check today can save you days of downtime tomorrow. Keep operations smooth, reduce downtime, and save on costly repairs with our expert Hydraulic Pump Repair Services. Contact us today to schedule a performance check or urgent repair- https://www.hydraulicpumprepair.in/ #hydraulicpumprepair #excellenthydraulicworks #hydraulicpump #pumprepairshop #hydraulicpumpservices #industrialmaintance #industrialservices0 Comments ·0 Shares ·32 Views ·0 Reviews -

Expert Tips for Parker Hydraulic Pump Care

Ever faced an unexpected machine breakdown just when the work is at its peak? Most of the time, it’s not the machine's fault; it’s because of our poor hydraulic pump maintenance. Regular care isn’t an option; it's survival for Parker hydraulic pumps.

Would you be willing to extend the life of your Parker hydraulic pump? Before it doesn't work, you can learn how to maintain it the right way.

Some reasons why your pump fails suddenly.

1. How *** contamination, overheating, and incorrect pressure settings destroy pump life.

2. The right maintenance intervals and *** types you must use.

Easy-to-follow tips to prevent cavitation, internal wear, and early breakdown.

3. Signs your hydraulic pump needs urgent attention (before it's too late!)

4. If you want to save money, reduce machine downtime, and extend your pump's lifespan, you must consider this to save the life of your parker hydraulic pump

Click below to read the full guide: https://excellenthydraulicpumprepair.mystrikingly.com/blog/parker-hydrauli-oump-maintance-guide

This detailed maintenance guide covers everything from early warning signs of wear to expert-level cleaning, *** change intervals, and troubleshooting tips. Whether you’re in construction, manufacturing, or agriculture.

#hydraulicrepair #parkerhydraulicpump #industrialhydraulicmachinery #industrialhydraulics #excellenthydraulicworks #hydraulicsystemexperts #heavyequipmentmaintenance

Expert Tips for Parker Hydraulic Pump Care Ever faced an unexpected machine breakdown just when the work is at its peak? Most of the time, it’s not the machine's fault; it’s because of our poor hydraulic pump maintenance. Regular care isn’t an option; it's survival for Parker hydraulic pumps. Would you be willing to extend the life of your Parker hydraulic pump? Before it doesn't work, you can learn how to maintain it the right way. Some reasons why your pump fails suddenly. 1. How oil contamination, overheating, and incorrect pressure settings destroy pump life. 2. The right maintenance intervals and oil types you must use. Easy-to-follow tips to prevent cavitation, internal wear, and early breakdown. 3. Signs your hydraulic pump needs urgent attention (before it's too late!) 4. If you want to save money, reduce machine downtime, and extend your pump's lifespan, you must consider this to save the life of your parker hydraulic pump Click below to read the full guide: https://excellenthydraulicpumprepair.mystrikingly.com/blog/parker-hydrauli-oump-maintance-guide This detailed maintenance guide covers everything from early warning signs of wear to expert-level cleaning, oil change intervals, and troubleshooting tips. Whether you’re in construction, manufacturing, or agriculture. #hydraulicrepair #parkerhydraulicpump #industrialhydraulicmachinery #industrialhydraulics #excellenthydraulicworks #hydraulicsystemexperts #heavyequipmentmaintenance0 Comments ·0 Shares ·32 Views ·0 Reviews -

Are KPM pumps suitable for continuous heavy-duty operations?

KPM pumps are specially designed for places where the machine runs day and night and the model is a heavy-duty design with high-pressure capability for long operating life. The K3VL and K3VG series in particular have been developed for applications where the machine has to operate day and night, non-stop, and at high pressures.

First of all, their design and build quality are so heavy that they can easily handle pressures up to 320 bar. This means that whether it is mining, construction, or any industrial machine, no matter how much load there is, these pumps can last.

Secondly, the parts used in them are hard-finished and quality-ground, which reduces wear and tear. The advantage of this is that the pump lasts for a long time without major repairs.

Thirdly, KPM hydraulic pumps have advanced settings like load sensing, pressure cut-off, and torque control. This means that the machine will take only as much flow and pressure as is needed—there will be no unnecessary power wastage, and both fuel/energy will be saved.

And yes, remember one thing for sure, the *** must be clean. If dirt, water, or metal particles get into the ***, the pump, be it a KPM hydraulic pump or any other brand, will break down quickly. Also, use the company-recommended fluid. KPM pumps are going to save money in the long run.

Book a free diagnosis or consultation today. Let your machines run better and longer.

No delay. No guessing. Tested by a professional for Rebuilding.

visit us- https://www.hydraulicpumprepair.in/kpm-hydraulic-pump.html

Are KPM pumps suitable for continuous heavy-duty operations? KPM pumps are specially designed for places where the machine runs day and night and the model is a heavy-duty design with high-pressure capability for long operating life. The K3VL and K3VG series in particular have been developed for applications where the machine has to operate day and night, non-stop, and at high pressures. First of all, their design and build quality are so heavy that they can easily handle pressures up to 320 bar. This means that whether it is mining, construction, or any industrial machine, no matter how much load there is, these pumps can last. Secondly, the parts used in them are hard-finished and quality-ground, which reduces wear and tear. The advantage of this is that the pump lasts for a long time without major repairs. Thirdly, KPM hydraulic pumps have advanced settings like load sensing, pressure cut-off, and torque control. This means that the machine will take only as much flow and pressure as is needed—there will be no unnecessary power wastage, and both fuel/energy will be saved. And yes, remember one thing for sure, the oil must be clean. If dirt, water, or metal particles get into the oil, the pump, be it a KPM hydraulic pump or any other brand, will break down quickly. Also, use the company-recommended fluid. KPM pumps are going to save money in the long run. Book a free diagnosis or consultation today. Let your machines run better and longer. No delay. No guessing. Tested by a professional for Rebuilding. visit us- https://www.hydraulicpumprepair.in/kpm-hydraulic-pump.html0 Comments ·0 Shares ·34 Views ·0 Reviews -

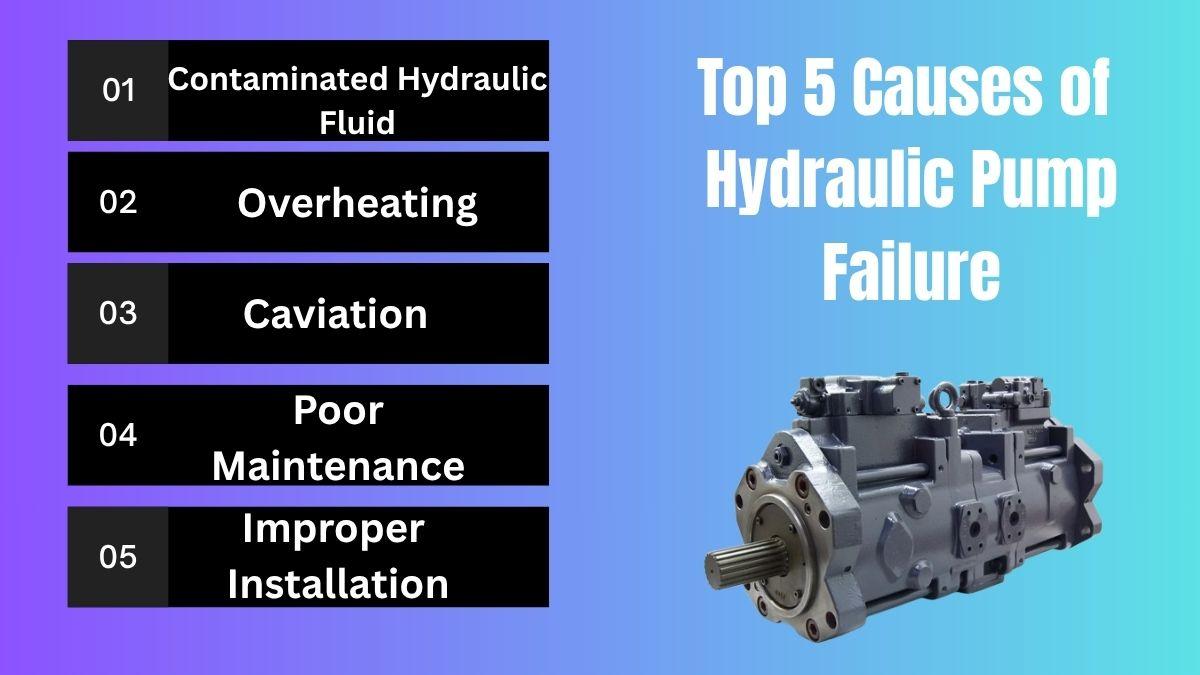

Top 5 Causes of Hydraulic Pump Failure

Hydraulic pumps play a vital role in powering heavy machines, but like any hard-working part, they can wear out, especially without regular care.

1. One of the most common reasons for failure is contaminated ***. When water, dust, or tiny metal bits get into the system, they grind against the internal parts and speed up damage.

2. Another big mistake is using the wrong type of hydraulic *** or cheap alternatives. This creates problems with the lubrication and leads to early wear and tear.

3. A less visible but deadly issue is cavitation; this happens when air gets trapped in the pump, creating bubbles that slowly eat away at the components.

4. Also, when a pump is run at too high pressure or overloaded, it puts unnecessary stress on seals and internal parts.

5. And finally, extreme temperatures, which lead to hot or cold, can ruin quality, making the whole system inefficient.

If you want your hydraulic system to last longer, regular checks and proper servicing are the way to go, and when things get tricky, trust only a skilled hydraulic pump repair technician who knows the brand inside out.

Read this blog for more information- https://www.zupyak.com/p/4640940/t/top-5-causes-of-hydraulic-pump-failure

If you are searching for experts to solve your pump query, you can trust Hydraulic pump repair services in Delhi NCR for the best service with over 27+years of repairing experience.

You can book a free diagnosis or consultation today. Let your machines run more efficiently and last longer.

No delay. No guessing. Tested by a professional for Rebuilding.

Call Now to Book or enquire- +91- 9953500755

#hydraulicrepair #exacavatorpump #industrialhydraulicmachinery #industrialhydraulics #excellenthydraulicworks #hydraulicsystemexperts #heavyequipmentmaintenanceTop 5 Causes of Hydraulic Pump Failure Hydraulic pumps play a vital role in powering heavy machines, but like any hard-working part, they can wear out, especially without regular care. 1. One of the most common reasons for failure is contaminated oil. When water, dust, or tiny metal bits get into the system, they grind against the internal parts and speed up damage. 2. Another big mistake is using the wrong type of hydraulic oil or cheap alternatives. This creates problems with the lubrication and leads to early wear and tear. 3. A less visible but deadly issue is cavitation; this happens when air gets trapped in the pump, creating bubbles that slowly eat away at the components. 4. Also, when a pump is run at too high pressure or overloaded, it puts unnecessary stress on seals and internal parts. 5. And finally, extreme temperatures, which lead to hot or cold, can ruin quality, making the whole system inefficient. If you want your hydraulic system to last longer, regular checks and proper servicing are the way to go, and when things get tricky, trust only a skilled hydraulic pump repair technician who knows the brand inside out. Read this blog for more information- https://www.zupyak.com/p/4640940/t/top-5-causes-of-hydraulic-pump-failure If you are searching for experts to solve your pump query, you can trust Hydraulic pump repair services in Delhi NCR for the best service with over 27+years of repairing experience. You can book a free diagnosis or consultation today. Let your machines run more efficiently and last longer. No delay. No guessing. Tested by a professional for Rebuilding. Call Now to Book or enquire- +91- 9953500755 #hydraulicrepair #exacavatorpump #industrialhydraulicmachinery #industrialhydraulics #excellenthydraulicworks #hydraulicsystemexperts #heavyequipmentmaintenance0 Comments ·0 Shares ·56 Views ·0 Reviews -

How often should I service my hydraulic pump?

You should service your hydraulic pump approximately every 500 to 1000 working hours, as recommended by the pump manufacturer, because machines operating in dusty, humid, or heavy load environments, more frequent checks are highly advisable. Regular maintenance keeps your pump running efficiently, prevents risk, and protects against sudden breakdowns that can stop your overall operations and cause expensive damage in the future. Common signs that your pump may be due for servicing include unusual noise, reduced pressure, and overheating. If you ignore these signs, this may lead to high costs in the future.

we understand how critical your hydraulic systems are to your business. You should call experts for pump repairing, they do preventive maintenance, and perform high-quality repairs using only genuine and branded parts because good servicing will definitely save your pump's life for the future and run smoothly without glitches .

If you are searching for a Hydraulic Pump Repair expert in Delhi NCR, you can contact us. We specialise in brands like Parker, Danfoss, Sauer-Danfoss, and more. Our commitment to fast service, fair pricing, and customer satisfaction makes us the trusted choice for industries across India.

Book a free diagnosis or consultation today. Let your machines run more efficiently and last longer.

No delay. No guessing. Tested by a professional for Rebuilding.

Visit us- https://www.hydraulicpumprepair.in/

Call Now to Book or enquire- +91- 9953500755

#hydraulicrepair #exacavatorpump #industrialhydraulicmachinery #industrialhydraulics #excellenthydraulicworks #hydraulicsystemexperts #heavyequipmentmaintenance

How often should I service my hydraulic pump? You should service your hydraulic pump approximately every 500 to 1000 working hours, as recommended by the pump manufacturer, because machines operating in dusty, humid, or heavy load environments, more frequent checks are highly advisable. Regular maintenance keeps your pump running efficiently, prevents risk, and protects against sudden breakdowns that can stop your overall operations and cause expensive damage in the future. Common signs that your pump may be due for servicing include unusual noise, reduced pressure, and overheating. If you ignore these signs, this may lead to high costs in the future. we understand how critical your hydraulic systems are to your business. You should call experts for pump repairing, they do preventive maintenance, and perform high-quality repairs using only genuine and branded parts because good servicing will definitely save your pump's life for the future and run smoothly without glitches . If you are searching for a Hydraulic Pump Repair expert in Delhi NCR, you can contact us. We specialise in brands like Parker, Danfoss, Sauer-Danfoss, and more. Our commitment to fast service, fair pricing, and customer satisfaction makes us the trusted choice for industries across India. Book a free diagnosis or consultation today. Let your machines run more efficiently and last longer. No delay. No guessing. Tested by a professional for Rebuilding. Visit us- https://www.hydraulicpumprepair.in/ Call Now to Book or enquire- +91- 9953500755 #hydraulicrepair #exacavatorpump #industrialhydraulicmachinery #industrialhydraulics #excellenthydraulicworks #hydraulicsystemexperts #heavyequipmentmaintenance0 Comments ·0 Shares ·68 Views ·0 Reviews -

Is your hydraulic pump giving you trouble?

Let us help you keep your operations running smoothly! At Excellent Hydraulics Works, we specialise in industrial hydraulic pump repair services to various industries such as manufacturing, construction, transport, and energy that rely on heavy machinery usage and require no downtime. Our team of experts provide quick and reliable hydraulic equipment repair that minimises your downtime and gets your machinery back in action.

DO not delay for any kind of issues- whether it is pump failures or you need a routine maintenance check, call expert. With a focus on quality service and affordable pricing, we ensure that your pumps perform efficiently, extending their lifespan and saving you money in the long run.

Our hydraulic pump repair services are designed to meet the specific needs of your business, ensuring that the repairs are as efficient as the equipment itself. So, if you need professional hydraulic system expert in Delhi NCR, don’t hesitate to reach out!

Contact us today at hydraulicpumpservice@gmail.com or visit our website at https://www.hydraulicpumprepair.in/industries.html to know about our detailed services offered.

Phone: +91-9810648026

Location: Bawana, Delhi-110039

Connect us on WhatsApp: +91- 9810648026

#hydraulicrepair #exacavatorpump #industrialhydraulicmachinery #industrialhydraulics #excellenthydraulicworks #hydraulicsystemexperts #heavyequipmentmaintenance

Is your hydraulic pump giving you trouble? Let us help you keep your operations running smoothly! At Excellent Hydraulics Works, we specialise in industrial hydraulic pump repair services to various industries such as manufacturing, construction, transport, and energy that rely on heavy machinery usage and require no downtime. Our team of experts provide quick and reliable hydraulic equipment repair that minimises your downtime and gets your machinery back in action. DO not delay for any kind of issues- whether it is pump failures or you need a routine maintenance check, call expert. With a focus on quality service and affordable pricing, we ensure that your pumps perform efficiently, extending their lifespan and saving you money in the long run. Our hydraulic pump repair services are designed to meet the specific needs of your business, ensuring that the repairs are as efficient as the equipment itself. So, if you need professional hydraulic system expert in Delhi NCR, don’t hesitate to reach out! Contact us today at hydraulicpumpservice@gmail.com or visit our website at https://www.hydraulicpumprepair.in/industries.html to know about our detailed services offered. 📞 Phone: +91-9810648026 📍 Location: Bawana, Delhi-110039 Connect us on WhatsApp: +91- 9810648026 #hydraulicrepair #exacavatorpump #industrialhydraulicmachinery #industrialhydraulics #excellenthydraulicworks #hydraulicsystemexperts #heavyequipmentmaintenance0 Comments ·0 Shares ·75 Views ·0 Reviews -

Best Construction and Earthmoving Hydraulic Repair Service in Delhi NCR

Is your construction machine showing signs of low pressure, overheating, or leakage? Many people face this problem, and they ignore it and make mistake. These are early warning signals that your hydraulic system needs attention. If you are ignoring them now, this can damage your machine for the future. So don’t delay for short-term investment; investing now will save your machine for future life.

To tackle this situation, we provide expert hydraulic Construction Equipment repair services in Delhi NCR including graders, loaders, backhoes, bulldozers, and excavators. We provide service for all brands like JCB, Komatsu, Volvo, CAT, and many more. Our team specializes in hydraulic pump repair, cylinder rebuilding, motor servicing, and valve troubleshooting. If you are in and searching for a repair expert, you can contact us because we provide service experts who use OEM-quality parts and cutting edge testing techniques, which will make your pump life better. We promptly identify issues and repair your hydraulic system as before. To meet strict performance requirements, every unit is thoroughly examined, cleaned, and repaired, and your pump is tested within your budget. We’ve handled hundreds of hydraulic repairs across Delhi NCR, dealing with low pressure, seal failure, fluid contamination, and more. Our in-depth repair guide breaks down each issue to get your system running smoothly again. Are you looking for a reliable partner for hydraulic repairs?

Contact us for quick assistance call us- +91-9953500755

Visit - https://www.hydraulicpumprepair.in/construction-and-earthmoving-hydraulic-repair-service.html

#excellenthydraulicpump #hydraulicconstruction #hydraulicrepairexperts #hydraulicrepairshop

#hydraulicrepair #industrialservice

Best Construction and Earthmoving Hydraulic Repair Service in Delhi NCR Is your construction machine showing signs of low pressure, overheating, or leakage? Many people face this problem, and they ignore it and make mistake. These are early warning signals that your hydraulic system needs attention. If you are ignoring them now, this can damage your machine for the future. So don’t delay for short-term investment; investing now will save your machine for future life. To tackle this situation, we provide expert hydraulic Construction Equipment repair services in Delhi NCR including graders, loaders, backhoes, bulldozers, and excavators. We provide service for all brands like JCB, Komatsu, Volvo, CAT, and many more. Our team specializes in hydraulic pump repair, cylinder rebuilding, motor servicing, and valve troubleshooting. If you are in and searching for a repair expert, you can contact us because we provide service experts who use OEM-quality parts and cutting edge testing techniques, which will make your pump life better. We promptly identify issues and repair your hydraulic system as before. To meet strict performance requirements, every unit is thoroughly examined, cleaned, and repaired, and your pump is tested within your budget. We’ve handled hundreds of hydraulic repairs across Delhi NCR, dealing with low pressure, seal failure, fluid contamination, and more. Our in-depth repair guide breaks down each issue to get your system running smoothly again. Are you looking for a reliable partner for hydraulic repairs? Contact us for quick assistance call us- +91-9953500755 Visit - https://www.hydraulicpumprepair.in/construction-and-earthmoving-hydraulic-repair-service.html #excellenthydraulicpump #hydraulicconstruction #hydraulicrepairexperts #hydraulicrepairshop #hydraulicrepair #industrialservice0 Comments ·0 Shares ·83 Views ·0 Reviews

More Stories