Sponsorizzato

Exploring HiTo Engineering’s Aluminum Coil Coating Line Technologies for Modern Manufacturing

In the competitive world of modern manufacturing, efficiency, durability, and finish quality are non-negotiable. HiTo Engineering has emerged as a significant player in this space, specializing in advanced aluminum coil coating line technologies. These integrated systems are engineered to apply precise, protective, and decorative coatings to coiled aluminum substrates before they are formed into final products. By investing in such technology, manufacturers can achieve remarkable consistency, reduce waste, and meet the stringent demands of industries ranging from construction and automotive to consumer electronics and appliances.

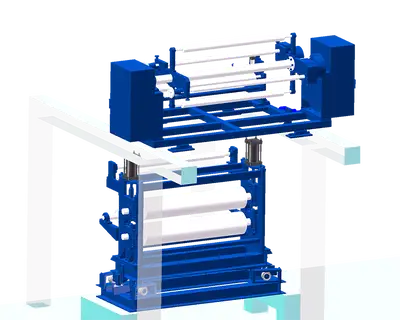

The Core Components of a Coil Coating Line

A HiTo Engineering aluminum coil coating line is not a single machine but a sophisticated, continuous production system. It typically begins with an uncoiler and entry accumulator, which feeds the aluminum coil seamlessly into the line. The metal then undergoes critical pre-treatment stages including cleaning and chemical treatment to ensure optimal coating adhesion. Following this, the coil passes through primer and topcoat application stations, often using precise roll coaters, and then into high-temperature curing ovens. The line concludes with a cooling section and a re-reeler that carefully winds the finished product. Each component is designed to operate in harmony, ensuring a flawless and efficient process from start to finish.

Precision Application and Curing Processes

The heart of the technology lies in its application and curing stages. HiTo Engineering utilizes state-of-the-art roll coating technology, which applies paints, primers, and protective coatings with exceptional uniformity and controlled thickness. This method is far superior to post-forming painting as it eliminates runs, sags, and uneven coverage. After application, the coated aluminum enters a multi-zone curing oven. These ovens are engineered to heat the metal rapidly and evenly, facilitating the cross-linking of polymers within the coating. This results in a finish that is not only visually perfect but also boasts superior mechanical properties like flexibility and hardness.

Advantages for Sustainable Manufacturing Practices

Sustainability is a cornerstone of modern industrial policy, and HiTo’s technologies contribute significantly here. The enclosed coil coating process is dramatically more environmentally friendly than traditional spray painting. It captures and contains Volatile Organic Compounds (VOCs) emitted from coatings, which are then typically treated by integrated incineration or recovery systems, converting them to harmless compounds. Furthermore, the process is highly efficient, generating virtually no overspray waste and using less energy per square foot of metal treated. This allows manufacturers to reduce their carbon footprint while complying with increasingly strict environmental regulations.

Enhancing Material Performance and Longevity

The benefits of using a HiTo coil coating line extend directly to the performance of the aluminum product itself. The coatings applied are rigorously tested to provide exceptional resistance to corrosion, UV radiation, and extreme weather conditions. This means products like building facades, automotive trim, and roofing materials have vastly extended lifespans, requiring less maintenance and replacement. The pre-coated aluminum is also more durable during the fabrication process; the cured finish is resistant to chipping, cracking, and scratching when the coil is later formed, punched, or cut into its final shape.

Integration with Smart Industry 4.0 Systems

Recognizing the shift towards digitalization, HiTo Engineering designs its lines for seamless integration with Industry 4.0 principles. Their systems are equipped with sophisticated sensors and programmable logic controllers (PLCs) that monitor every variable—from coating viscosity and oven temperature to line speed and tension. This data is fed into a central control system, allowing for real-time adjustments and predictive maintenance. This smart manufacturing approach minimizes downtime, ensures consistent quality, and provides manufacturers with valuable data analytics to further optimize their production processes.

Meeting the Demands of Diverse Global Industries

The versatility of HiTo’s aluminum coil coating technology makes it indispensable across a wide spectrum of global industries. In architecture, it enables the production of vibrant and long-lasting panels for curtain walls and roofs. The automotive sector relies on it for durable trim and under-hood components. Appliance manufacturers use it to create the pristine, easy-to-clean surfaces on refrigerators and ovens. Even the tech industry utilizes pre-coated aluminum for sleek electronics housings. By offering customizable solutions for different coating types and production volumes, HiTo Engineering provides a critical technology that empowers modern manufacturing to be more efficient, sustainable, and innovative.

Categorie

Leggi tutto

Originally published by Quantzig: Boost Home Furnishing Retail with Strategic Assortment Optimization: Merchandising Analytics Introduction: In the competitive landscape of home furnishing retail, data-driven merchandising strategies are essential for success. This case study showcases how Quantzig, a leading analytics firm, collaborated with a prominent home furnishings retailer to...

Market Dynamics: The Pepper Spray Market is driven by consumers' rising awareness of self-defense. The primary driver of pepper spray purchases is the rise in crimes like eve teasing, rape, kidnapping, murder, and human trafficking. Numerous tools or weapons are used for self-defense, including an aluminum baseball bat, a self-vigilant alarm, a pocketknife, self-defense key cases, and silver...