Commandité

Polymerization Initiator Market Growth in Emerging Economies

Polymerization Initiator Market Growth in Emerging Economies

The global polymerization initiator market is witnessing substantial growth, particularly in emerging economies where industrialization, urbanization, and rising incomes are creating new opportunities across various sectors. Polymerization initiators are essential in the production of polymers used in manufacturing a wide range of products, from packaging materials to automotive components. As these emerging economies continue to modernize, the demand for polymers—and by extension, polymerization initiators—continues to increase. This article explores the key drivers, opportunities, and challenges shaping the growth of the polymerization initiator market in these regions.

What Are Polymerization Initiators?

Polymerization initiators are substances that initiate or speed up the polymerization process, where monomers are transformed into polymers. These initiators, such as peroxides and azo compounds, are integral to industries like automotive, construction, electronics, packaging, and healthcare. By enabling the synthesis of polymers with tailored properties—such as strength, flexibility, or conductivity—polymerization initiators ensure that the final products meet specific industry standards.

In emerging economies, the increasing demand for polymer-based materials in construction, packaging, automotive, and electronics is driving the need for polymerization initiators.

Key Drivers of Market Growth

1. Industrialization and Infrastructure Development

Emerging economies are experiencing rapid industrialization. As countries like India, China, Brazil, and several Southeast Asian nations transition from agrarian economies to industrial hubs, demand for construction materials, packaging products, and automotive components is surging. Polymers play a crucial role in these industries, with materials such as epoxy resins, polyurethanes, and acrylics being used in coatings, adhesives, and insulation.

Polymerization initiators enable the efficient production of these polymers, ensuring the desired properties for durability and resistance. As these economies invest heavily in infrastructure and urbanization, the need for polymer-based materials—and consequently, for polymerization initiators—is growing.

2. Booming Automotive Industry

The automotive sector in emerging markets is expanding rapidly, driven by an increase in disposable income and urbanization. Lightweight materials that enhance fuel efficiency are a key focus, and polymers, including composites, thermoplastics, and elastomers, are used in vehicle manufacturing. For instance, bumpers, dashboards, and interior components are increasingly made from polymer-based materials.

Polymerization initiators are essential in producing these materials, ensuring the polymers have the required strength, thermal stability, and resistance to wear and tear. As emerging economies ramp up vehicle production, the demand for polymerization initiators is expected to rise.

3. Expanding Packaging Industry

Packaging is a significant consumer of polymer materials, with the demand driven by the growth of consumer goods, e-commerce, and food and beverage industries. Packaging materials like polyethylene, polypropylene, and polystyrene are essential in producing bottles, containers, and films.

Polymerization initiators help produce these packaging materials by enabling the polymerization of monomers into strong, flexible, and transparent polymers. As packaging requirements evolve toward sustainability and recyclability, the demand for innovative polymer materials—and the initiators required to produce them—is growing.

4. Rising Electronics Production

The electronics industry is flourishing in emerging economies, with countries like China, India, and Brazil becoming global hubs for electronic device manufacturing. Polymers are used in various electronic components, such as semiconductors, printed circuit boards (PCBs), and encapsulants.

Polymerization initiators are vital in creating high-performance polymers that meet the electrical, thermal, and mechanical properties needed for electronics. As emerging markets expand their electronics production, the need for polymerization initiators will continue to grow.

5. Healthcare and Pharmaceutical Growth

The healthcare and pharmaceutical sectors in emerging economies are experiencing rapid growth, with rising health awareness and better access to healthcare. Polymers are used in medical devices, drug delivery systems, and packaging.

Polymerization initiators are important in the production of pharmaceutical-grade polymers, including those used for controlled-release drug formulations and biodegradable medical implants. As healthcare infrastructure improves in emerging economies, the demand for these polymer-based materials will increase, further driving the demand for polymerization initiators.

Opportunities for Polymerization Initiator Manufacturers

1. Asia-Pacific: A Key Growth Region

Asia-Pacific represents the largest growth opportunity for the polymerization initiator market. Countries like China and India, with their rapidly expanding industrial sectors, are seeing a surge in demand for polymers. China, already a major global player in polymer production, is expected to continue driving market growth. Other countries in Southeast Asia also offer substantial opportunities due to industrial expansion and a growing manufacturing base.

2. Sustainability Focus

As environmental concerns increase, emerging economies are placing more emphasis on sustainable materials. Biodegradable and recyclable polymers are gaining traction, particularly in packaging. Polymerization initiators are essential for developing these eco-friendly alternatives, positioning manufacturers who produce sustainable initiators to benefit from this growing trend.

3. Strategic Local Manufacturing

Emerging economies often face supply chain challenges, such as inconsistent raw material availability or transportation inefficiencies. Local manufacturing offers a solution, enabling polymerization initiator companies to lower costs, improve supply chain reliability, and cater to the specific needs of regional markets. Partnerships with local manufacturers will also provide valuable market insights, ensuring better product fit for regional demands.

Challenges in Emerging Economies

1. Regulatory Barriers

Many emerging economies are still developing their regulatory frameworks concerning chemicals, including polymerization initiators. Navigating these complex regulations and ensuring compliance can be time-consuming and costly for global companies. Regulatory differences across countries can also complicate market entry and expansion efforts.

2. Infrastructure Issues

Despite significant progress in infrastructure development, many emerging economies still face challenges related to transport logistics, power supply inconsistencies, and access to raw materials. These issues can cause delays in production and distribution, limiting the ability of manufacturers to meet the growing demand for polymer-based materials.

3. Price Sensitivity

Emerging economies are often price-sensitive, with manufacturers and consumers looking for cost-effective solutions. While polymerization initiators are crucial in polymer production, the price of these materials can be a barrier, especially in highly competitive markets. Companies will need to focus on offering affordable solutions while maintaining product quality.

Conclusion

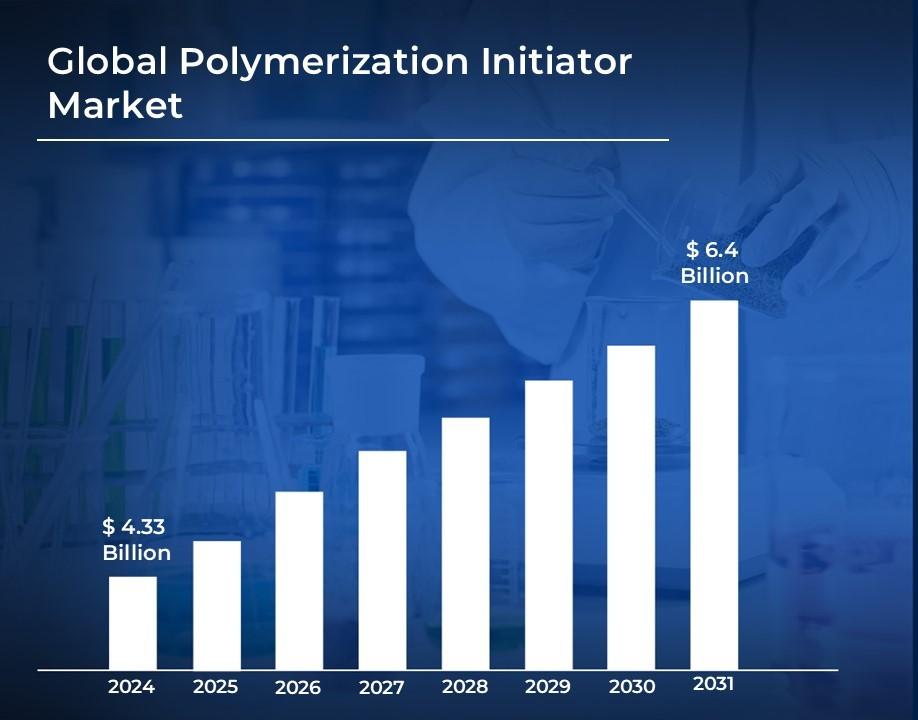

The polymerization initiator market is on an upward trajectory in emerging economies, driven by factors such as industrialization, expanding automotive, electronics, and packaging sectors, as well as rising healthcare demand. While there are challenges such as regulatory complexities, infrastructure limitations, and price sensitivity, the opportunities for growth in regions like Asia-Pacific and Latin America are substantial. By investing in local manufacturing, sustainability initiatives, and strategic partnerships, polymerization initiator manufacturers can capitalize on the growing demand for polymer-based materials in these fast-developing markets. As these economies continue to evolve, the polymerization initiator market is set to experience strong growth in the coming years.