Sponsorizzato

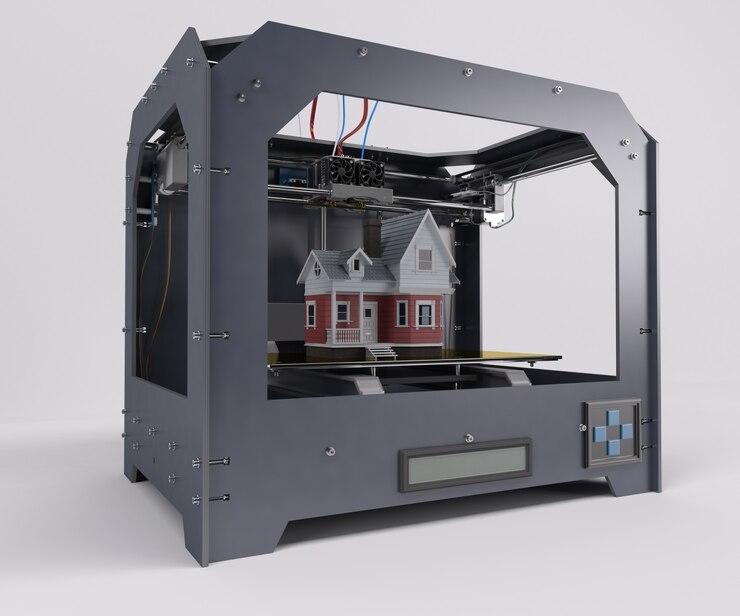

Desktop 3D Printer Technology Glimpse into the Future

The desktop 3D printer market has been growing rapidly in recent years, thanks to technological advancements that have made 3D printing more accessible and efficient for a wide range of industries. Desktop 3D printers, which are compact, cost-effective, and easy to use, are transforming the way businesses and individuals approach product design, prototyping, and manufacturing.

Key Technologies Driving the Desktop 3D Printer Market:

-

Fused Deposition Modeling (FDM): FDM technology is the most commonly used 3D printing method in desktop printers. In this process, a thermoplastic filament is heated and extruded through a nozzle to build up the model layer by layer. FDM printers are popular for their affordability, ease of use, and the ability to work with a wide range of materials, making them a go-to choice for small-scale production, prototyping, and educational purposes.

-

Stereolithography (SLA): SLA is another key technology that is gaining traction in the desktop 3D printer market. This technology uses a laser to cure liquid resin into solid layers, which are then built up to create the final object. SLA printers are known for their high precision and ability to produce intricate, detailed models with a smooth finish. This makes them ideal for industries such as jewelry, dental, and medical applications, where high-quality prints are essential.

-

Selective Laser Sintering (SLS): Although traditionally used in industrial-grade 3D printers, SLS technology is also being adapted for desktop models. SLS works by using a laser to fuse small particles of powdered material, such as nylon, into solid structures. Desktop SLS printers are beneficial for creating functional prototypes, as well as durable parts and products that require complex geometries and strength.

-

Multi Jet Fusion (MJF): MJF is a relatively new 3D printing technology that is revolutionizing desktop 3D printers. It uses a combination of heat and a binding agent to fuse powdered materials, creating parts with excellent mechanical properties. Although still in the early stages for desktop applications, MJF has the potential to significantly impact industries such as automotive, aerospace, and healthcare.

Advancements in Material Technology:

As desktop 3D printing technology advances, so does the development of new materials. The availability of a wide range of materials is enabling greater customization and functionality in printed products. From thermoplastics to metals, resins, and even biomaterials, desktop 3D printers are capable of producing parts with varied physical properties.

The rise of composite filaments, which combine materials such as carbon fiber, fiberglass, and metal, has expanded the capabilities of desktop 3D printers. These advanced materials allow for the production of lightweight, strong, and durable parts, making them suitable for industries that require high-performance materials.

Cloud-Based and Software Integration:

Another technological development that is shaping the desktop 3D printer market is the integration of cloud-based platforms and software solutions. Cloud-based 3D printing allows users to send print jobs remotely, access printing resources, and manage workflows more effectively. In addition, advanced software is improving the precision and efficiency of 3D printing, enabling faster print times, better surface finishes, and enhanced accuracy.

Conclusion:

The desktop 3D printer market is evolving rapidly, with new technologies continually enhancing capabilities and expanding applications. As technology continues to advance, the accessibility of desktop 3D printing will further empower businesses, educators, and hobbyists to innovate and create with ease. With improved materials, advanced software, and more diverse printing technologies, the future of desktop 3D printing looks promising, especially in industries that rely on rapid prototyping, customization, and low-volume production.