Revolutionizing Surface Cleaning with Laser Metal Cleaner: A Future-Ready Solution

In today’s fast-paced industrial world, the demand for efficient, eco-friendly, and cost-effective cleaning solutions is more critical than ever. Traditional cleaning methods, such as chemical cleaning, abrasive blasting, and mechanical scrubbing, often involve harmful chemicals, excessive waste, and time-consuming processes. However, the emergence of laser technology has introduced a breakthrough solution—laser metal cleaner. These devices offer precise, eco-friendly cleaning with minimal wear and tear on the surface, making them an ideal choice for industries worldwide.

What is a Laser Metal Cleaner?

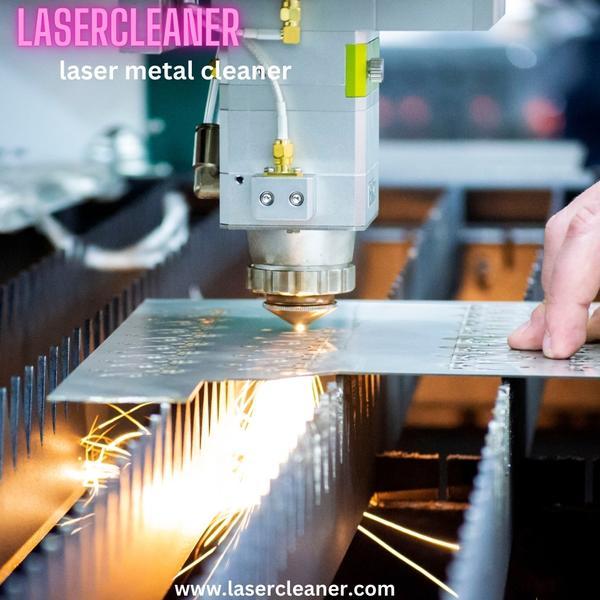

A laser metal cleaner is an advanced cleaning technology that utilizes high-intensity laser beams to remove contaminants such as rust, paint, oils, and grease from metal surfaces. The system works by focusing a laser on the surface of the metal, where the intense heat generated by the laser beam causes the contaminants to evaporate or be blown away by the resulting pressure. This cleaning method is fast, effective, and gentle on the material underneath, ensuring that the surface remains undamaged.

Why Choose a Laser Metal Cleaner?

There are several compelling reasons why laser metal cleaners are becoming the go-to solution for businesses across industries:

1. Eco-Friendly and Chemical-Free

Unlike traditional cleaning methods, which often rely on harmful chemicals, a laser metal cleaner uses only light and heat. This makes the process completely environmentally friendly. No harmful chemicals are released into the atmosphere, and there is no need for chemical waste disposal, significantly reducing the environmental footprint of your operations.

2. Precision and Efficiency

Laser cleaning offers unparalleled precision. The laser beam can be finely controlled to target only the contaminants, ensuring that no damage is done to the underlying metal surface. Whether it’s rust removal or paint stripping, laser cleaners can clean intricate parts without affecting their integrity. The process is fast and efficient, significantly reducing downtime in production environments.

3. Reduced Maintenance Costs

Laser cleaning systems are low-maintenance and durable, offering a long service life. Since there are no mechanical parts involved that can wear out, there’s less risk of frequent breakdowns or the need for costly repairs. This results in reduced maintenance costs and less operational downtime.

4. Versatility in Applications

Laser metal cleaning can be used in a wide range of applications across various industries, including automotive, aerospace, manufacturing, and metalworking. Whether you're cleaning industrial machinery, preparing surfaces for welding or coating, or removing contaminants from delicate components, laser cleaners provide a versatile solution for a variety of cleaning tasks.

5. No Risk of Contamination

Unlike abrasive cleaning methods, which can leave behind residue or damage the surface, laser cleaning is non-contact. This ensures that there is no risk of introducing new contaminants to the surface. It also eliminates the risk of surface deformation, making it ideal for delicate or high-precision metal parts.

How Laser Metal Cleaners Benefit Your Business

Adopting a laser metal cleaning system can bring numerous benefits to your business:

- Cost Savings: Although the initial investment in a laser cleaning machine may be higher than traditional methods, the long-term cost savings are significant. Reduced maintenance, fewer consumables, and faster cleaning times result in a more cost-efficient process overall.

- Improved Productivity: Laser cleaners offer fast, effective cleaning that minimizes downtime and increases throughput in production environments.

- Enhanced Quality: Clean, contaminant-free surfaces lead to better performance in subsequent processes like welding, coating, or assembly, ensuring superior product quality.

Conclusion

Laser metal cleaning is transforming the way industries approach surface cleaning. With its precision, efficiency, and eco-friendly advantages, it offers a compelling alternative to traditional cleaning methods. Investing in a laser metal cleaner not only helps improve operational efficiency but also contributes to a greener, more sustainable future for your business. As industries continue to embrace automation and innovation, laser cleaning stands as a prime example of how technology is shaping the future of manufacturing and maintenance.

Are you ready to upgrade your cleaning process? Consider the efficiency and versatility of a laser metal cleaner—your gateway to a cleaner, greener, and more efficient future.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness