Sponsorizzato

3D Printing Extrusion Materials Market Set for Rapid Growth Through 2024

The global 3D printing extrusion materials market is anticipated to witness high growth owing to increasing demand from end-use industries such as industrial, healthcare, and aerospace & defense. Rapid prototyping provides efficient product development and reduces waste, driving demand for these materials.

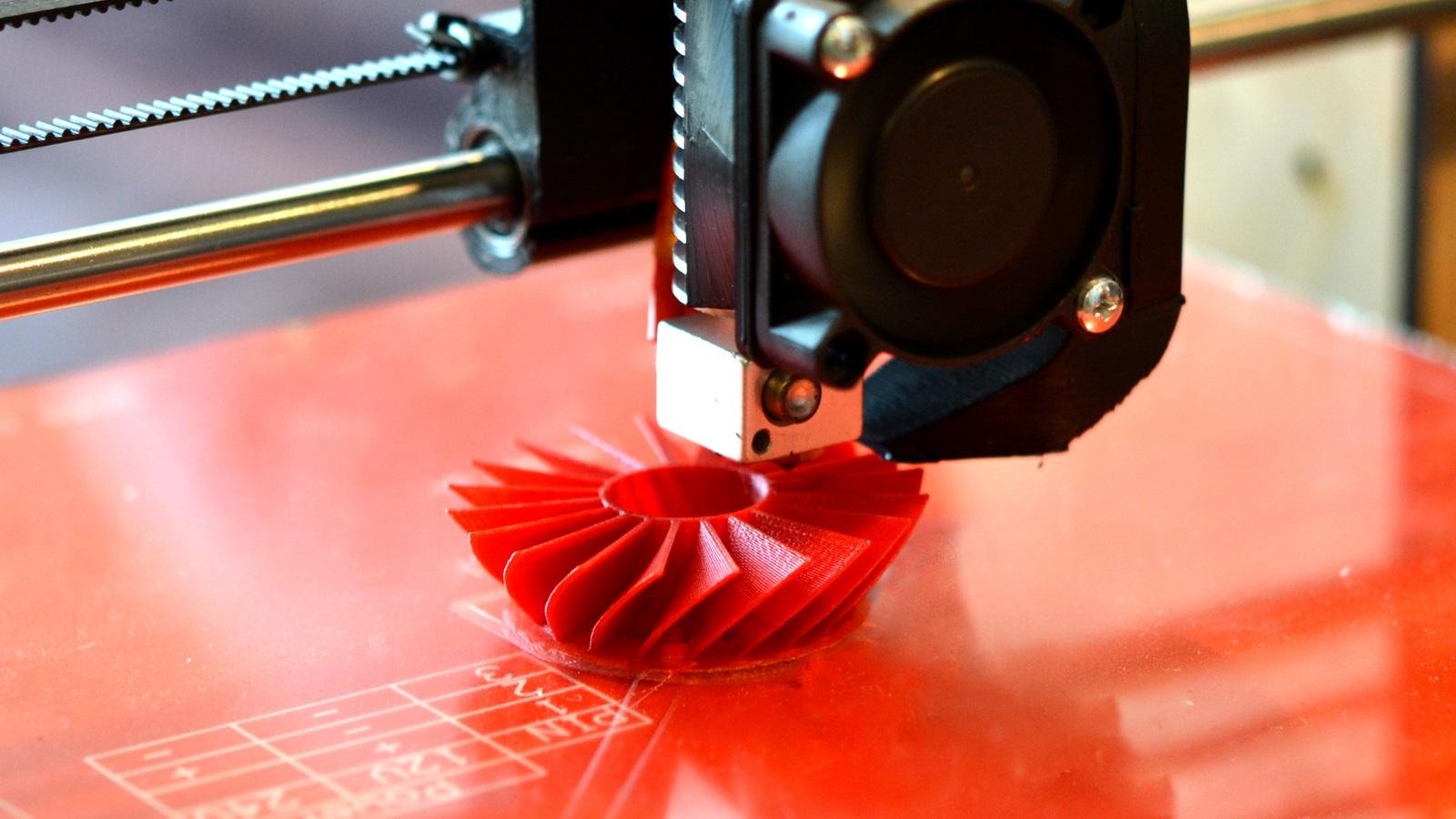

3D printing extrusion materials such as photopolymers, filaments, polyamides, bio-materials and composites are used to manufacture three-dimensional objects from digital design data. Advantages include high precision, complex geometries, reduced material wastage and improved design flexibility. Industries increasingly rely on 3D printing for rapid tooling, functional prototypes and end-use parts. The need for faster and affordable prototyping as well as customizable, durable parts is fueling adoption across sectors.

The Global 3D printing extrusion materials Market is estimated to be valued at US$ 5.27 Bn in 2024 and is expected to exhibit a CAGR of 19% over the forecast period 2024 To 2031.

Key Takeaways

Key players operating in the 3D printing extrusion materials are 3D Systems Corporation, Stratasys Ltd., Materialise NV, EOS GmbH, Arkema S.A., SABIC, Evonik Industries AG, DuPont de Nemours Inc., BASF SE, Dow Chemical Company, HP Inc., Royal DSM N.V., EnvisionTEC GmbH, CRP Group., and Carbon, Inc.

The key opportunities in the market include the development of new bio-based materials, composites and nanocomposites suitable for various high-performance applications. Wide range of material options allows for customizability as per specific customer and application requirements.

Globally, major players are expanding their geographical footprint by establishing production facilities in emerging markets like Asia Pacific and Middle East & Africa. The abundant raw material availability and subsidized capital expenditures attract companies to set up manufacturing hubs, catering to the rising local demand.

Market drivers: The boost in global manufacturing activities post-COVID, especially in the automotive and aerospace industries is expected to drive the demand for advanced 3D printing extrusion materials Demand . Continuous technological advancements enabling the use of new materials for high-resolution printing will also support market revenue growth over the coming years.

Market restraints: High material costs, limited part sizes due to machine size constraints and lack of standardized processes continue to restrain widespread commercialization of certain 3D printing applications. Concerns around operational safety when using newer photopolymers and nanocomposites may also impede market growth to some extent over the near future.

Segment Analysis

The 3d printing extrusion materials market is segmented by type, form, end user industry and geography. The type segment include plastic, metal and ceramic materials. Plastic materials dominates the market and holds around 60% share. This is because plastics like photopolymers, ABS and PLA are most commonly used for low cost prototyping and manufacturing applications. Flexibility, broad range of applications and ease of use makes plastic materials preferred choice over metal and ceramic for 3d printing.

In terms of form, filament form holds major share of around 70% due to its applicability in FDM 3D printing technology which is widely used. However, powder form segment is growing at higher rate driven by increasing adoption of binder jetting and powder bed fusion 3D printing processes in industries.

End user industries of 3d printing extrusion materials includes automotive, aerospace & defense, healthcare, consumer goods and industrial. Automotive industry dominates and is one of fastest growing segments due to utilization of 3D printing for prototyping, tooling and manufacturing applications. This helps automakers to reduce cost and time to market.

Global Analysis

Regionally, North America dominates the 3d Printing Extrusion Materials Market Regional Analysis holding around 40% share driven by presence of major players and growing adoption across major end user industries in the US and Canada. Europe is second largest market supported by government funding for 3D printing research and applications across automotive and healthcare sectors in Germany, UK and France. Asia Pacific region is fastest growing market lead by China, Japan and India. Countries in APAC are witnessing increased investments in 3D printing for local manufacturing to reduce import dependence. Growth is also supported by expansion of global players and indigenous technology development in the region. The Middle East & Africa and South America are at nascent stage but expected to witness significant growth during forecast period.

Get More Insights On 3D printing extrusion material Market

About Author

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91