-

4 Posts

-

0 Photos

-

0 Videos

-

16/11/1996

-

Followed by 0 people

Recent Updates

-

What are the components of NVH?

NVH (Noise, Vibration, and Harshness) is the measurement, examination, and adjustment of the vibration and noise properties of automobiles. Engineers should continually effort on combating the vibration, noise, and harshness that affect a customer’s experience when riding in a vehicle and also threaten the automobile's strength. Sources of NVH are found outside and inside of the car and examples include cooling fans, transmission, panel holes, fluid routing lines, doors, brakes, alternator, road noise and wind, actuators, and mounting brackets.

Automotive NVH Materials Market Growth Insights@ https://www.psmarketresearch.com/market-analysis/automotive-nvh-materials-market

In automotive design, NVH is handled by lessening the transfer of unwanted sounds and vibrations into the passenger area. This is attained by the use of sound and vibration absorbing and checking NVH components which advance the performance, comfort, and safety of the vehicle. Automotive NVH items are commonly small components that are made from foam, rubber, or other materials.

Reducing NVH On Fluid Routing Lines

Custom rubber tube grommets lessen noise, vibration, and harshness by stopping metal-to-metal interaction and limiting the movement of metal tubing. Such kinds of grommets generally include custom-made internal ribs that give the liquid routing line assemblies the capability to be supple, while majorly decreasing the volume of vibration that happens.

They characteristically also require to be made with a custom non-conductive EPDM rubber

formulation to help in the prevention of electric corrosion.

Metal bracket rubber inserts are made to avoid metal-to-metal interaction with the bracket and metal tubing and lessen vibration with their ribbed design.

Fuel Tank NVH

Fuel tanks are huge apparatuses that can generate a lot of NVH-associated problems if not engineered well.

An often way fuel tank builders combat NVH is by utilizing rubber pads that are located between the fuel tank and the vehicle body.

Fuel system mechanisms need complex materials and designs to endure the harsh environments they might be put through. When fuel might come in contact with the rubber, it's important to select a chemically resilient rubber, like HNBR and Viton.

Drivers

In the current scenario, automobile weight lessening has become one of the key problems in the automotive sector. Lightweight cars save power, experience reduced brake and tire wear, and also aid cut down emissions. Lightweight vehicles also advance fuel economy and support in controlling NVH.

Conclusion

NVH within the automotive industry has become an important characteristic of building a consumer-absorbed vehicle. Car purchasers don't want to hear unwanted noise, and they for sure don't want to contract with the worry of components vibrating against each other, resulting in part failure.

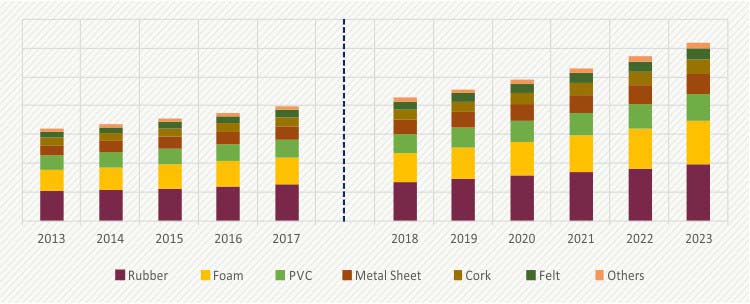

What are the components of NVH? NVH (Noise, Vibration, and Harshness) is the measurement, examination, and adjustment of the vibration and noise properties of automobiles. Engineers should continually effort on combating the vibration, noise, and harshness that affect a customer’s experience when riding in a vehicle and also threaten the automobile's strength. Sources of NVH are found outside and inside of the car and examples include cooling fans, transmission, panel holes, fluid routing lines, doors, brakes, alternator, road noise and wind, actuators, and mounting brackets. Automotive NVH Materials Market Growth Insights@ https://www.psmarketresearch.com/market-analysis/automotive-nvh-materials-market In automotive design, NVH is handled by lessening the transfer of unwanted sounds and vibrations into the passenger area. This is attained by the use of sound and vibration absorbing and checking NVH components which advance the performance, comfort, and safety of the vehicle. Automotive NVH items are commonly small components that are made from foam, rubber, or other materials. Reducing NVH On Fluid Routing Lines Custom rubber tube grommets lessen noise, vibration, and harshness by stopping metal-to-metal interaction and limiting the movement of metal tubing. Such kinds of grommets generally include custom-made internal ribs that give the liquid routing line assemblies the capability to be supple, while majorly decreasing the volume of vibration that happens. They characteristically also require to be made with a custom non-conductive EPDM rubber formulation to help in the prevention of electric corrosion. Metal bracket rubber inserts are made to avoid metal-to-metal interaction with the bracket and metal tubing and lessen vibration with their ribbed design. Fuel Tank NVH Fuel tanks are huge apparatuses that can generate a lot of NVH-associated problems if not engineered well. An often way fuel tank builders combat NVH is by utilizing rubber pads that are located between the fuel tank and the vehicle body. Fuel system mechanisms need complex materials and designs to endure the harsh environments they might be put through. When fuel might come in contact with the rubber, it's important to select a chemically resilient rubber, like HNBR and Viton. Drivers In the current scenario, automobile weight lessening has become one of the key problems in the automotive sector. Lightweight cars save power, experience reduced brake and tire wear, and also aid cut down emissions. Lightweight vehicles also advance fuel economy and support in controlling NVH. Conclusion NVH within the automotive industry has become an important characteristic of building a consumer-absorbed vehicle. Car purchasers don't want to hear unwanted noise, and they for sure don't want to contract with the worry of components vibrating against each other, resulting in part failure. WWW.PSMARKETRESEARCH.COMAutomotive NVH Materials Market | Industry Share Report 2023Automotive noise, vibration, and harshness (NVH) materials market is estimated to be valued at $7,579.8 million in 2017 and is projected to reach $11,467.5 million by 2023, witnessing a CAGR of 7.2% during the forecast period.0 Comments 0 Shares 677 Views 0 ReviewsPlease log in to like, share and comment!

WWW.PSMARKETRESEARCH.COMAutomotive NVH Materials Market | Industry Share Report 2023Automotive noise, vibration, and harshness (NVH) materials market is estimated to be valued at $7,579.8 million in 2017 and is projected to reach $11,467.5 million by 2023, witnessing a CAGR of 7.2% during the forecast period.0 Comments 0 Shares 677 Views 0 ReviewsPlease log in to like, share and comment! -

Growing Demand for Personal Care Products Drives 1,3-Butylene Glycol Market GrowthGrowth drivers such as the booming food, plasticizer, inks, pharmaceutical, and paints and coatings industries, the burgeoning demand for pharmaceutical-grade of 1,3-butylene glycol, and the rising need for this chemical from the cosmetic sector will help the 1,3-butylene glycol market exhibit a CAGR of 5.9% between 2022 and 2030. In contemporary years, the cosmetic industry is witnessing...0 Comments 0 Shares 1K Views 0 Reviews

-

Rapid Industrialization in APAC Driving Specialty Chemicals DemandSpecialty chemicals or performance chemicals are used in the production of numerous goods in several end-use industries. Such chemicals are directed toward specific services and consumer needs, rather than general use. These chemical products add significant value to a wide range of products, such as detergents, electronics, paints, and petroleum products. For example, automakers use such...0 Comments 0 Shares 1K Views 0 Reviews

-

Online Pharmacy Market Trends, Key Drivers and Outlook ReportThe online pharmacy market size is predicted to reach $261,684.5 million by 2030 from $68,382.3 million in 2021, at a CAGR of 16.1%. This has a lot to do with the sharp increase in the number of internet users. Moreover, due to the pandemic, the lockdown became one of the key driving factors, as, confined to their homes and needing medicines, people turned to online pharmacies. The traditional...0 Comments 0 Shares 1K Views 0 Reviews

More Stories