The Benefits and Advantages of Upgrading to the Cardone 66-5444 CV Axle Assembly for Off-Road or High-Performance Driving

The Benefits and Advantages of Upgrading to the Cardone 66-5444 CV Axle Assembly for Off-Road or High-Performance Driving

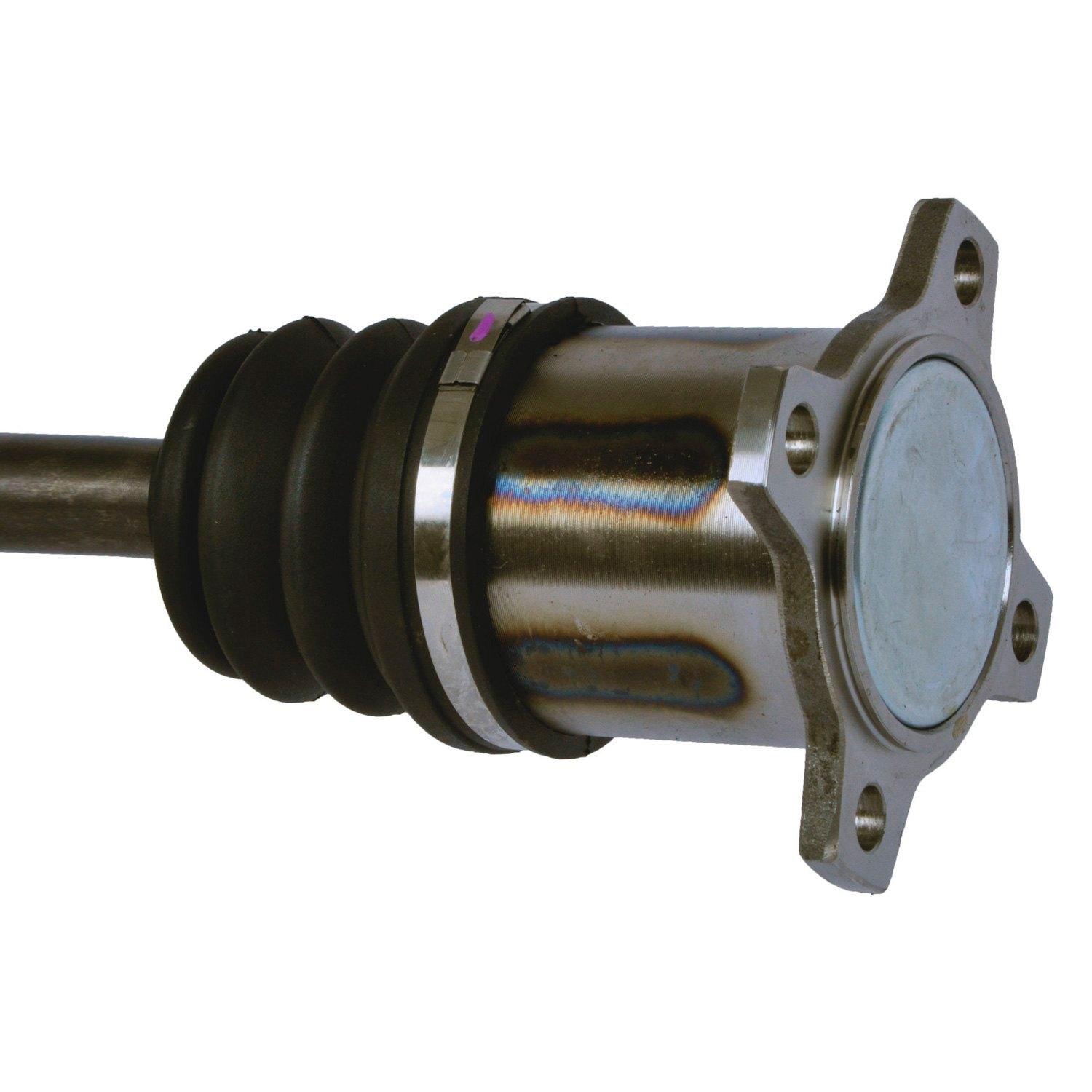

The Cardone 66-5444 Axle is a high-performance CV (constant velocity) axle assembly that is designed for off-road and high-performance driving. This CV axle assembly is a direct replacement for the original equipment (OE) axle and is manufactured using the highest quality materials and advanced manufacturing techniques. The result is an axle assembly that is stronger, more durable, and more reliable than the OE axle.

In this blog post, we will discuss the benefits and advantages of upgrading to the Cardone 66-5444 Axle for off-road or high-performance driving.

Benefits of Upgrading to the Cardone 66-5444 Axle

- Increased Strength and Durability: The Cardone 66-5444 Axle is made of high-strength steel and is designed to withstand the stresses of off-road and high-performance driving. This means that it is less likely to bend or break under heavy loads or during high-speed maneuvers.

- Improved Handling and Performance: The Cardone 66-5444 Axle is designed to provide improved handling and performance compared to the OE axle. This is because it is a direct replacement for the OE axle and is manufactured to the same specifications. This means that it will fit and perform just like the OE axle, but with the added strength and durability of the high-strength steel.

- Longer Service Life: The Cardone 66-5444 Axle is designed to last longer than the OE axle. This is because it is made of high-strength steel and is designed to withstand the stresses of off-road and high-performance driving. This means that it will last longer and require less maintenance than the OE axle.

- Easy Installation: The Cardone 66-5444 Axle is designed to be a direct replacement for the OE axle. This means that it will fit and perform just like the OE axle, and it can be easily installed without any special tools or equipment. This makes it a great option for anyone looking to upgrade their vehicle's axle without the hassle of complicated installation.

Semi-Floating vs Full Floating Axle, what's the Difference?

Semi-floating and full-floating axles are two different types of axle designs used in vehicles. The main difference between the two is how the weight of the vehicle is supported and how the wheels are attached to the axle.

A semi-floating axle is designed with a single hub that attaches the wheel to the axle. The hub is supported by a single bearing, and the weight of the vehicle is supported by the axle shaft. This design is commonly used in light-duty vehicles such as cars and trucks, as well as some heavy-duty vehicles such as buses and RVs.

A full-floating axle, on the other hand, is designed with a separate hub that attaches the wheel to the axle. The hub is supported by two bearings, and the weight of the vehicle is supported by the hubs rather than the axle shaft. This design is commonly used in heavy-duty vehicles such as trucks, buses and tractors.

The main advantage of a full-floating axle is that it can handle a higher load capacity than a semi-floating axle. This is because the weight of the vehicle is supported by the hubs rather than the axle shaft, which reduces the stress on the shaft and allows it to handle more weight. Additionally, full-floating axles are more durable and less likely to fail under heavy loads.

In summary, the main difference between semi-floating and full-floating axles is the way weight is supported, and how the wheels are attached to the axles. Semi-floating axles are typically used in light-duty vehicles, while full-floating axles are used in heavy-duty vehicles. Full-floating axles can handle a higher load capacity and are more durable than semi-floating axles.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness