إعلان مُمول

Planetary Gearbox Design: Compact, Powerful, and Elegant

In the modern era of mechanical design and automation, achieving high torque in a compact envelope is often a key challenge. One of the most elegant solutions to that challenge is the planetary gearbox (also sometimes called epicyclic gearbox). In this article, we explore the fundamentals, design considerations, and advanced strategies behind planetary gearbox design — useful for engineers, machine designers, and technically curious readers on MeVirtuoso.

What Is a Planetary Gearbox?

A planetary gearbox consists of three main components:

-

Sun Gear – the central gear, typically connected to the input or driving shaft

-

Planet Gears – several gears (usually 3 or more) that orbit around the sun gear, mounted on a planet carrier

-

Ring Gear (or internal gear) – an outer gear with internal teeth meshing with the planets

The planets mesh simultaneously with both the sun and ring gears. Depending on which component is held fixed or actuated, the gearbox can yield different speed reduction or multiplication ratios, torque outputs, and even reverse directions.

Because multiple planet gears share the load—and because forces tend to cancel radially—the planetary arrangement is both compact and capable of high power density.

Key Design Considerations

When designing a planetary gearbox, several interdependent factors must be balanced carefully. Here are the major ones:

1. Gear Ratio & Tooth Counts

The target reduction (or multiplication) ratio largely governs the tooth counts of sun, planet, and ring gears. A standard relation is:

i1V=1+zringzsuni_{1V} = 1 + \frac{z_{\text{ring}}}{z_{\text{sun}}}i1V=1+zsunzring

if the ring gear is fixed and the carrier is the output.

That formula constrains how many teeth each gear must have and what combinations are feasible. The geometric spacing (center distances) must also align so that sun-planet and planet-ring meshing align properly.

2. Number of Planets & Load Distribution

Increasing the number of planet gears helps spread the torque load, reduce bending stress on individual teeth, and increase stiffness. However, more planets complicate the carrier and ring geometry, and may reduce the clearance space.

Uniform load sharing depends on good manufacturing tolerances, precise alignment, and sometimes slight tooth or profile modifications. New research proposes regulating backlash (via small assembly adjustments) to equalize load more uniformly among the planets.

3. Gear Type: Spur vs Helical vs Modified

-

Spur gears are simpler and cheaper, but can be noisy and less smooth under high load or high speed conditions.

-

Helical gears bring more tooth contact, smoother operation, and higher load capability; but they create axial thrust loads that bearings must absorb.

-

Modified tooth surfaces (crowned, profile-shifted, or optimized) can help reduce misalignment effects, backlash, and nonuniform load among planets. NASA investigations into new planetary face-gear designs illustrate how shaping tooth surfaces can improve performance.

4. Backlash, Tolerances & Transmission Error

Backlash must be carefully controlled: too much backlash causes inaccuracy and shock, too little can lead to binding under misalignments or thermal distortions. Designers often balance between minimised backlash and safe clearance.

Transmission error (the small deviation in angular position due to elastic deformation, gear deflection, misalignment) is a primary source of vibration and noise. Design strategies often aim to distribute error harmonics or cancel them via phasing among planets.

5. Bearing & Support Design

Supporting the planets on bearings is nontrivial due to limited space. Bearing choices and clearances must resist radial and axial loads (especially for helical gear arrangements). Excessive bearing stress leads to fatigue and early failure.

High speeds and centrifugal forces on the planets also impose design limits: planets spinning on their own axes undergo internal stresses and thermal issues.

6. Thermal, Lubrication & Material Choices

Because planetary gearboxes often operate in compact housings, heat dissipation is a concern. Material selection (hardened steels, surface treatments) and lubrication strategies (oil bath, splash lubrication, advanced lubricants) are essential to maintain durability.

The thermal expansion of parts must be considered so misalignment or tooth interference does not creep in under operating temperature.

Advanced & Recent Trends

The last decade has seen many advances in planetary gear design, driven by computational optimization and novel manufacturing:

-

Multi-objective optimization approaches now find gear designs that concurrently minimize mass, transmission error, and power loss. One recent work demonstrates how to trade among these objectives in planetary sets.

-

Reliability optimization using surrogate models (e.g. Kriging) or genetic algorithms has been studied to improve the fault tolerance of planetary gear systems.

-

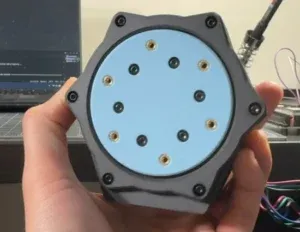

Additive manufacturing (3D printing) is being explored to build planetary gearboxes with complex internal geometries, lightweight structures, and embedded cooling channels. A recent study printed a 3D planetary gear set, achieving good performance with careful tolerancing.

-

Differential planetary arrangements allow variable-speed outputs under different loads, useful in adaptive transmissions or machine drives. A design example shows how a planetary differential gearbox can modulate output speed inversely with loading.

Practical Tip: A Step-by-Step Design Workflow

Here’s a simplified workflow that a designer might follow:

-

Define requirements: torque, speed, size constraints, power loss, stiffness, life.

-

Choose topology: simple single-stage, compound planet, differential, or custom variant.

-

Estimate gear ratio & tooth counts: satisfying meshing and geometric constraints.

-

Select number of planets & arrangement: balance load vs complexity.

-

Preliminary gear geometry: modules, helix angles, profile shifts.

-

Finite element / analytical modeling: to assess tooth stress, deflection, transmission error.

-

Optimize: perhaps via multiobjective methods (mass, error, efficiency).

-

Detail bearings, housing, lubrication.

-

Prototype & test: validate in real-world conditions, refine as needed.

Why Planetary Gearboxes Matter to MeVirtuoso Audiences

At MeVirtuoso, readers are often interested in showcasing engineering elegance and functional innovation. Planetary gearboxes stand at the intersection of compact mechanical beauty and high-performance utility. Whether your application is in robotics, precision motion control, automotive systems, or industrial automation, a well-designed planetary gearbox can deliver torque, stiffness, reliability, and space efficiency in a way few other transmissions can.

الأقسام

إقرأ المزيد

Roof painting may not be the first thing that comes to mind when thinking about home maintenance, but it plays a vital role in protecting your property—especially in Wellington. With its high winds, salty air, and strong UV exposure, Wellington is tough on roofs. Working with professional roof painters in Wellington ensures that your home not only looks great but is also shielded against...

Starzbet Mobil Uygulama: Kolay ve Hızlı Bahis Deneyimi Starzbet Mobil Uygulama, bahis severlerin her an her yerden bahis yapmalarını sağlayan yenilikçi bir platformdur. Günümüzde bahis dünyasında mobil uygulamaların önemi giderek artmakta ve Starzbet, bu ihtiyaca en iyi şekilde cevap veren uygulamalardan biri olarak öne çıkmaktadır. Mobil uygulama...