Patrocinado

Electrostatic Discharge Packaging Market Expands as ESD Protection Gains Importance in Supply Chains

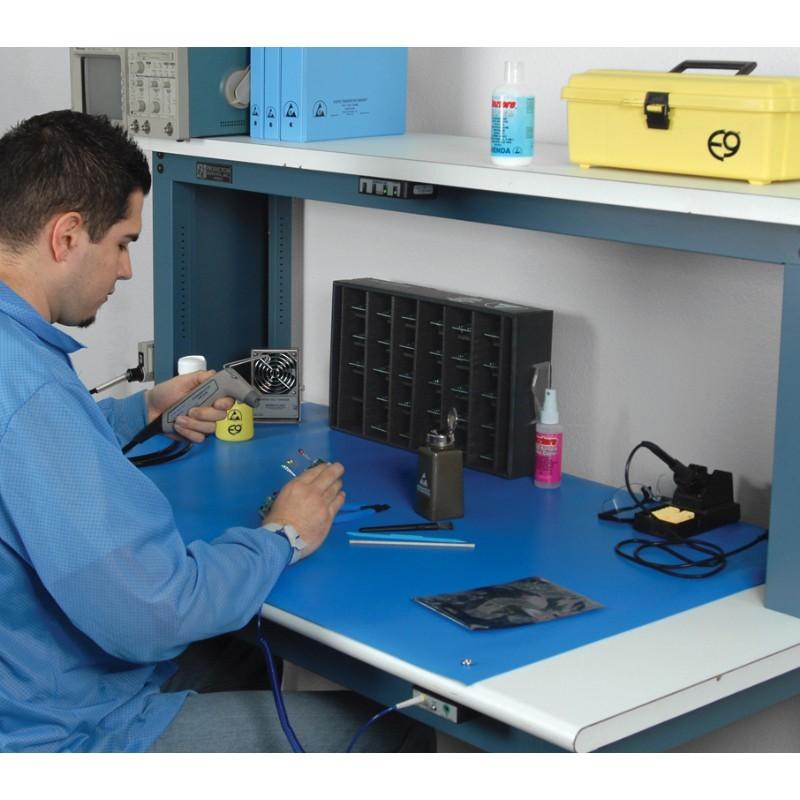

The Electrostatic Discharge Packaging Market is witnessing robust growth fueled by the increasing global demand for sensitive electronic components across industries. These packaging solutions play a critical role in safeguarding microelectronics, semiconductors, and other static-sensitive devices from electrostatic discharges that could result in irreversible damage. As technological advancements drive miniaturization and higher performance of electronic devices, the need for reliable ESD protection becomes even more vital across the supply chain.

Growing Demand Across Key End-Use Industries

The proliferation of consumer electronics, automotive electronics, and high-performance computing is a major factor propelling the demand for electrostatic discharge (ESD) packaging solutions. In consumer electronics, smartphones, laptops, and gaming devices incorporate sensitive integrated circuits that are vulnerable to even minor static charges. The automotive sector, driven by the boom in electric vehicles (EVs) and advanced driver-assistance systems (ADAS), also depends heavily on ESD packaging for protecting automotive-grade electronic components.

Moreover, the semiconductor industry—a key end-user—is experiencing exponential growth, further accelerating demand. Foundries, chipmakers, and electronics contract manufacturers are implementing strict ESD protocols, with packaging being one of the frontline defenses.

Types of ESD Packaging and Material Innovation

The market offers a range of ESD packaging types, including trays, bags, boxes, clamshells, and foams. Each is engineered to meet specific performance requirements and static protection levels. Depending on the application, packaging may offer antistatic, conductive, or dissipative properties.

Recent developments in material science have also enhanced the quality and sustainability of ESD packaging. Biodegradable polymers, carbon-filled plastics, and metalized films are being explored and increasingly adopted. These not only ensure effective protection but also address environmental concerns tied to plastic waste—especially relevant as global regulatory pressure mounts for eco-friendly packaging alternatives.

Market Drivers

Several macro- and microeconomic factors are driving the growth trajectory of the electrostatic discharge packaging market:

-

Rising Electronics Production: Rapid industrialization and increasing disposable incomes, particularly in Asia-Pacific countries like China, South Korea, and India, are fostering large-scale electronics production, thus amplifying demand for ESD packaging.

-

Stringent Regulatory Standards: Governmental and industry standards such as ANSI/ESD S20.20 and IEC 61340 are mandating stricter ESD-safe environments in production and logistics, making compliant packaging essential.

-

Global Semiconductor Boom: The expansion of 5G networks, AI, IoT, and data centers is pushing the boundaries of semiconductor innovation, increasing the need for safe handling and shipment of advanced microchips.

-

Supply Chain Complexity: With electronics components traveling across continents, the risk of static damage during storage and transit is higher than ever. This necessitates reliable ESD packaging for extended protection.

Challenges in the Market

Despite promising growth, the market is not without challenges. One major barrier is the high cost associated with specialty materials and manufacturing processes for ESD packaging. Especially for small and medium-sized enterprises, these costs can be a deterrent.

In addition, lack of awareness in some regions, especially among non-technical handlers in logistics or warehouse operations, can limit the adoption of proper ESD-safe practices, reducing the effectiveness of the packaging.

Furthermore, sustainability concerns persist. While innovations are underway, many ESD packaging materials are still non-biodegradable and difficult to recycle, making eco-conscious alternatives a growing area of focus for manufacturers.

Regional Insights

The Asia-Pacific region dominates the global market, driven largely by China’s and Taiwan’s role as electronics manufacturing hubs. North America and Europe follow, with strong investments in automotive electronics and semiconductor design. Meanwhile, emerging economies in Latin America and Africa are showing early signs of adopting ESD-safe practices, often led by multinational corporations expanding into those markets.

Emerging Trends and Opportunities

Several trends are reshaping the ESD packaging market landscape:

-

Automation and Smart Packaging: Integration of RFID tags and sensors for real-time tracking and ESD condition monitoring is gaining popularity.

-

Custom Packaging Solutions: With device miniaturization, customized ESD packaging designs tailored to specific components are increasingly in demand.

-

Circular Economy Initiatives: Manufacturers are exploring take-back programs and reusable ESD containers to align with circular economy models.

There is also growing venture capital interest in startups offering innovative materials and digital solutions for static protection—signaling future acceleration in both innovation and competition.

Conclusion

The Electrostatic Discharge Packaging Market is evolving rapidly in response to growing technological sophistication, complex supply chains, and stringent quality demands. As electronics become more integral to our daily lives and global industries, the role of ESD-safe packaging becomes increasingly indispensable. With innovation in materials, customization, and sustainability gaining momentum, the market is poised for strong and sustained growth in the coming decade.