Sponsored

Kaizen Continuous Improvement: Transforming Processes One Step at a Time

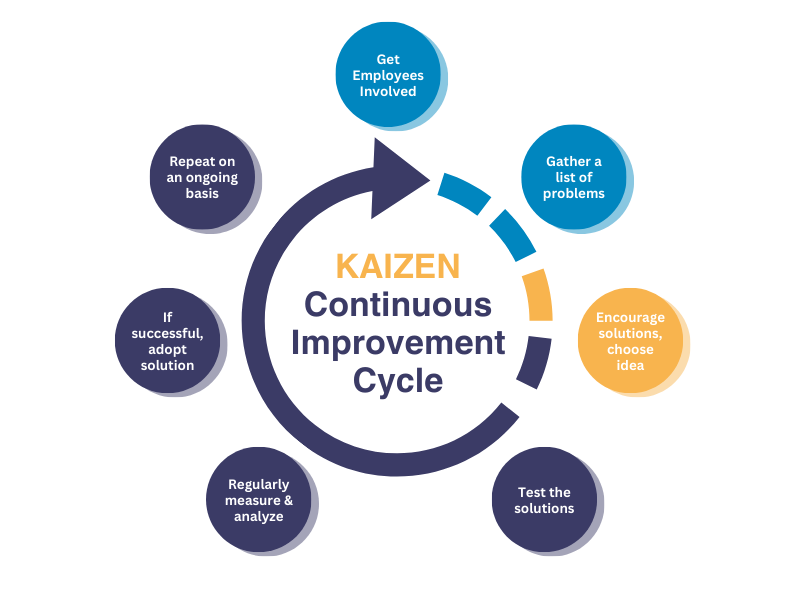

Introduction to Kaizen Continuous Improvement

In a world where businesses constantly push to become faster, better, and more efficient, Kaizen stands out as a timeless, people-focused approach to progress. The Japanese word Kaizen means "change for better," and that’s exactly what it does — it transforms work, one small improvement at a time.

But Kaizen isn’t just a buzzword. It’s a culture, a mindset, and a strategy rolled into one. Whether you’re running a factory floor, managing a software team, or even organizing your kitchen, kaizen continuous improvement can help streamline operations, reduce waste, and inspire innovation.

The Core Principles of Kaizen

Incremental Improvements

Unlike large, expensive overhauls, Kaizen is all about baby steps. It promotes gradual progress made consistently over time. Instead of reinventing the wheel, you simply make it roll a little smoother every day.

Respect for People

Kaizen honors everyone in the organization—from executives to janitors. It trusts that employees closest to the work know where improvements can be made. Their ideas matter, and their voices are heard.

Eliminating Waste (Muda)

One of the cornerstones of Kaizen is identifying and reducing muda, or waste. Whether it’s wasted time, materials, or effort, Kaizen helps eliminate inefficiencies that drain productivity and profits.

The Role of Kaizen in Modern Business

Kaizen in Lean Manufacturing

Kaizen fits perfectly within lean manufacturing, where the goal is to maximize value while minimizing waste. By continuously improving processes, manufacturers can cut costs, increase efficiency, and improve product quality.

How Kaizen Applies Across Departments

You don’t need a factory to benefit from Kaizen. Marketing, HR, IT — every department can implement it. From streamlining onboarding processes to improving customer service scripts, the possibilities are endless.

The Power of Daily Kaizen

Daily Kaizen means making micro-improvements every single day. It becomes part of your routine, like brushing your teeth. Over time, those little tweaks lead to big transformations.

Kaizen Event: What It Is and Why It Matters

Definition of a Kaizen Event

A Kaizen event (sometimes called a Kaizen Blitz) is an intensive, short-term project where a team focuses on improving a specific process. It usually lasts 3-5 days and brings together cross-functional teams to tackle challenges head-on.

Step-by-Step Breakdown of a Kaizen Event

Planning

Start with identifying the problem. What process is underperforming? Once defined, gather the right team and set clear goals.

Execution

This is where the magic happens. Observe, measure, brainstorm, and implement changes quickly. Teams work hands-on to improve the process in real-time.

Review and Standardization

After the changes are made, document the new process. Train others and create standard operating procedures to maintain the improvements.

When to Host a Kaizen Event

A Kaizen event is perfect when a process needs a quick fix or when a cross-functional team needs to realign. It’s also ideal before launching a new workflow or system.

Kaizen in Manufacturing

Streamlining Production with Kaizen

Kaizen has revolutionized manufacturing worldwide. From assembly lines to quality control, it helps companies do more with less — less waste, less downtime, and fewer defects.

Real-Life Examples of Kaizen Manufacturing

Toyota, the birthplace of Kaizen, famously uses it to fine-tune its production system. Workers suggest thousands of small improvements annually, many of which are implemented on the spot.

Benefits of Kaizen in Industrial Settings

-

Reduced operational costs

-

Higher productivity

-

Better quality products

-

Increased employee morale

-

Shorter lead times

Daily Kaizen: The Power of Small Daily Wins

Encouraging a Daily Kaizen Mindset

Foster a culture where employees ask themselves, “What can I improve today?” This mindset creates momentum and keeps innovation flowing from the ground up.

Tools and Techniques for Everyday Improvement

-

Suggestion boxes

-

Daily team huddles

-

Visual management boards

-

Feedback loops

These tools make it easy for anyone to contribute to continuous improvement.

Key Tools Used in Kaizen Implementation

5S Methodology

Sort, Set in order, Shine, Standardize, and Sustain — these steps help keep workspaces clean, organized, and efficient.

Value Stream Mapping

Visualize your workflow from start to finish to find where time and resources are being wasted.

PDCA (Plan-Do-Check-Act) Cycle

The PDCA cycle is the heartbeat of Kaizen. It’s a repeatable loop for solving problems and improving processes.

Cultural Transformation Through Kaizen

Building a Continuous Improvement Culture

Kaizen isn’t a one-off project — it’s a mindset. Companies that truly embrace Kaizen bake it into their culture, making it a daily part of their operations.

Leadership’s Role in Sustaining Kaizen

Leaders must lead by example. When they embrace change, encourage feedback, and support experimentation, employees feel empowered to do the same.

Challenges in Implementing Kaizen

Resistance to Change

People get comfortable with the status quo. Change, even for the better, can feel scary. Clear communication and leadership support are key.

Misunderstanding the Philosophy

Some companies treat Kaizen like a one-time fix instead of an ongoing journey. This short-term thinking can cause the whole system to crumble.

Sustainability Issues

Keeping momentum is hard. Regular training, open communication, and leadership involvement help Kaizen stick for the long haul.

Conclusion

Kaizen continuous improvement isn’t just a productivity hack — it’s a philosophy that, when embraced fully, can transform an entire organization from the inside out. By making small, consistent changes and encouraging everyone to participate, you create a system that not only adapts to change — it thrives on it.

So whether you’re hosting a full-blown Kaizen event, implementing daily Kaizen, or using Kaizen in manufacturing, one thing is clear: the road to excellence is paved with tiny, intentional steps.

FAQs

1. What are the 5 principles of Kaizen?

The five key principles are: know your customer, let it flow, go to Gemba (where the work happens), empower people, and be transparent.

2. How long does a Kaizen event typically last?

Most Kaizen events last 3 to 5 days, but they can vary depending on the scope of the problem.

3. Is Kaizen only for manufacturing?

Not at all! Kaizen is widely used in healthcare, software, education, and even personal productivity.

4. How does Kaizen differ from Six Sigma?

Kaizen focuses on incremental changes and team collaboration, while Six Sigma is more data-driven and often involves large-scale changes.

5. What is the first step in starting Kaizen?

Start by identifying a small area for improvement and engaging the people directly involved in that process. Then, build momentum from there.