Sponsored

Top 5 Must-Have Powder Coating Equipment for Professional Finishing Results

The powder coating has emerged as a common finishing metal parts because it is environment friendly; gives professional finish and stretches its life time. As opposed to conventional painting the method of powder coating involves calculations on charges of powder material that is electrostatic and a process of heating to form a very durable and smooth looking finish that is not susceptible to the effects of chipping, scratching and fading. Still, to produce the effects of a professional level, you should possess the necessary gear. When you are establishing a small business or redefining your current operation, selecting the right tools is very important.

We discuss below the 5 most crucial equipment all the professional finishers ought to possess to achieve consistent high quality at all times.

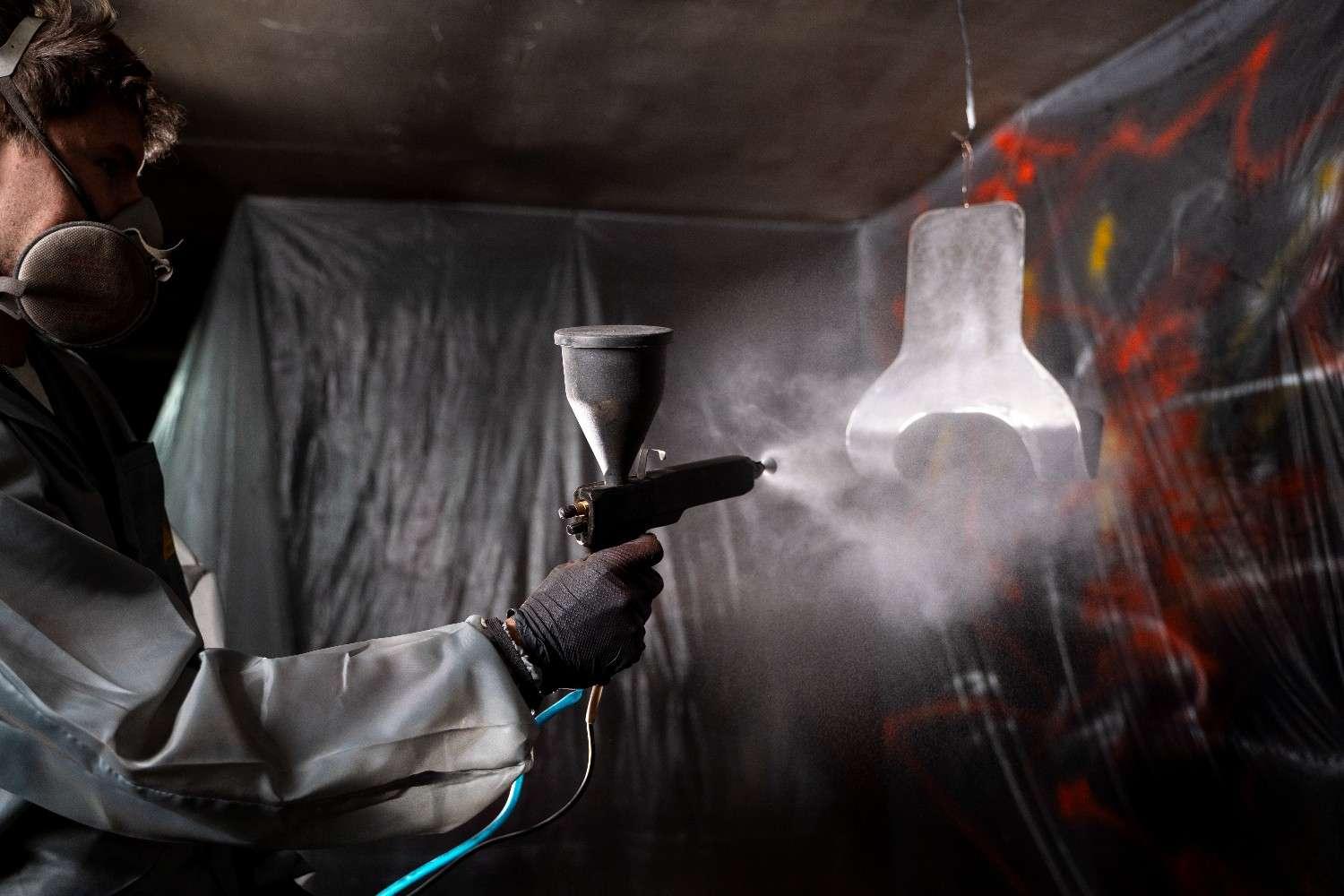

1. Powder Coating Spray Gun System

The spray gun system is the core of any powder coating set up. This machine maintains the powder particles in an electrostatically-charged state during the spraying process which is by using a grounded metal object. The charged particles stick to the surface until they are melted in an oven.

Spray guns come in various forms, entry level and the expensive ones as used on industry levels. The quality of a professional-grade gun provides a higher standard of control when it comes to voltage, airstream and powder channeling which directly affects the smoothness of the finish. Ask the technological weapon that can be adjusted, comes with interchangeable nozzles, and built with a rugged construction.

By purchasing a quality spray gun, not only will the finished product meet high standards but also will lead to the minimization of waste and re-work, turning this instrument into one of the most significant in your tool box.

2. Curing Oven

After the application of this powder, it is then followed by curing the treated item using a highly hot oven. The powder is liquefied by the curing oven and then durable finish hardened in a continuous, smooth coating. Temperature and time should be exact and usually somewhere between 375 and 400 F (190 and 204 C) and 10 to 20 minutes, depending on the recommendations of the company that makes the powders.

There are also ovens with different sizes; the smallest which can fit on a benchtop and the larger ones that are of the land category where it is used in industrial scales of work. The diameter of the oven must be of the same size as the largest item you intend to coat. Even briefly heat spread is important, thus, it makes sense to buy a good oven, where the inside temperatures remain constant.

Even the most diligently-applied product cannot use a professional finish without the right curing oven. It is a backbone of every successful powder coating business.

3. Powder Booth (Spray Booth)

A powder booth (or a spray booth) will help to hold an overspray and keep your working place clean. It enhances safety and efficiency in that it regulates powder flow, not to mention safeguarding the operator, reusability of powder and reuse. Booths can be as basic open faced enclosures, or they can be fully enclosed with ventilation, lights and air filters.

To make it professional one requires a booth that has a high-efficiency particulate air (HEPA) filter and a powerful exhaust fan. This arrangement assists to keep the air clean and reduce the chances of pollution of other components or working locations. When you intend to change colors of powders frequently, you may want to use a booth that involves simple cleaning of surfaces and easy to change the system of powder.

A properly designed booth can simplify the process, minimise the amount of wasted material and contribute significantly towards the quality of consistent finishes of any powder coating equipment.

4. Air Compressor and Air Filtration System

Powder coating spray guns require clean and dry air in order to operate effectively. It is at that point that a good air compressor and filtration system comes to the rescue. The powder is atomized using compressors that supply the required airflow that forces the powder to the workpiece. Nonetheless, compressed air is likely to be saturated with moisture and oil, which will destroy the coating procedure.

The air supply is fresh and dry because it has been purified under the influence of an air filtration system. A multi-staged filtration unit, water separator, oil separator, and desiccant dryer works excellent in professional applications. A steady airflow and cleanliness are essential to keep high finish quality and avoids the creation of fish eyes or milling bumps.

The type of compressor to use is selecting a more reliable one with sufficiently good tank size and pressure range (80-120 PSI commonly) to be able to operate your spray gun with ease especially when it experiences extended usage.

5. Grounding System

Grounding is not given attention but is indeed a must in any powder coating process. With a good grounding system, the charged powder will adhere well to the workpiece in an efficient manner causing little or no overspray which means that finish adhesion becomes good. Uneven coatings, thin spots and material wastage is possible when there is poor grounding.

Grounding A grounding rod or cable is applied to a metal object being coated to provide an electrical connection. In bigger installations, conductive hangers or grounding grids may be called upon. Keeping contacts clean and rust-free helps increase performance and grounding excellence as well as dependable finishes.

Although this element would appear to be just a small part, it is a significant element in terms of efficiency and effectiveness of your entire powder coating equipment set up.

Final Thoughts

And when it comes to professional powder coating, being equipped is not a matter of convenience and luxury, it is a matter of needs. Every part of your assembly, everything simple like a spray gun, up to a grounding system, has its own part in the creation of that perfect, lasting finish your customers demand. There is no question that when it comes to establishing a new shop to start in order to enhance your services with a view of streamlining your operations, using quality powder coating machinery is a sure-shot way of earning your money.

Check your volume requirements, space where you will be operating, and the kind of material you may be coating before buying. Probably with properly equipped facilities and a minimum of practice, even the small-scale can obtain results which are as good as those of the big industrial shops.

Categories

Read More

In recent years, educational platforms have rapidly evolved by adopting mechanisms once exclusive to the world of entertainment and gaming. Surprisingly, some of the most effective mechanics now used in learning apps originate from online casinos. Features such as reward systems, progress tracking, variable rewards, and streak preservation significantly increase user engagement and learning...

The global contrast media injectors market size reached USD 1.05 Billion in 2022 and is expected to register a revenue CAGR of 4.83% during the forecast period, according to the latest analysis by Emergen Research. The increasing prevalence of cancer, neurological disorders, and other conditions is one of the key factors driving revenue growth of the market. The prevalence of chronic diseases...