Patrocinados

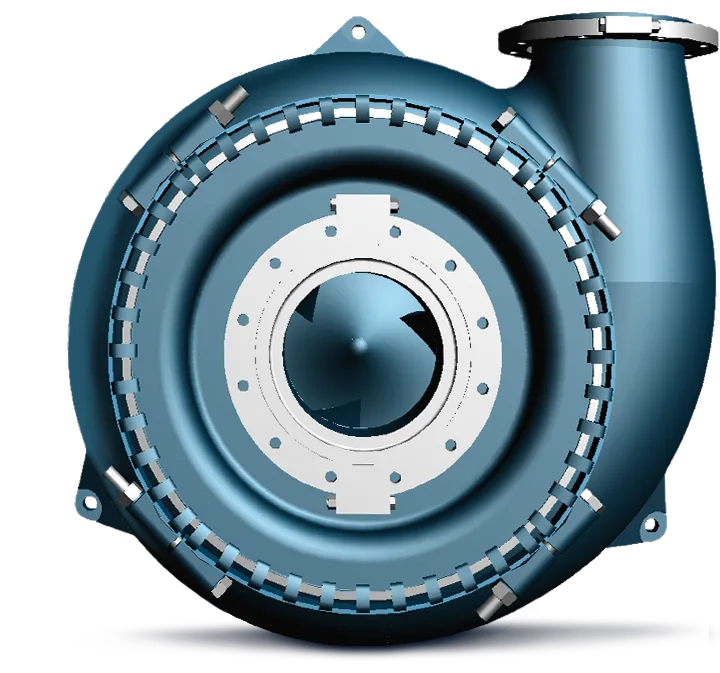

CNSME Pump: The Slurry Pump Manufacturer Committed to Service Life

CNSME Pump has established itself as a leading force in the slurry pump industry, driven by a fundamental commitment to enhancing the service life of its equipment. In industries such as mining, mineral processing, and chemical production, equipment failure due to wear and tear can lead to significant operational disruptions and financial losses. Recognizing these challenges, CNSME has placed durability and longevity at the core of its product development philosophy. Their pumps are engineered not just for high performance but also to withstand the intense demands of abrasive and corrosive slurry environments. This unwavering focus on service life ensures that clients benefit from equipment that maintains peak operational efficiency over extended periods, reducing maintenance costs and minimizing downtime.

Advanced Material Selection for Extended Wear Resistance

One of the hallmarks of CNSME’s approach to maximizing pump service life is the meticulous selection of materials. The company employs high-chrome alloys, rubber linings, and ceramic composites designed specifically for maximum wear resistance. These materials are chosen after rigorous testing under simulated operating conditions, ensuring they can withstand prolonged exposure to high-impact solids, chemical corrosion, and erosive forces. Such materials significantly reduce the frequency of component replacements, extending the operational lifespan of each pump. CNSME also innovates by developing new composite materials that optimize performance and durability, further pushing the boundaries of how long slurry pumps can function reliably under extreme conditions.

Engineering Design for Longevity and Reliability

CNSME’s commitment to service life isn’t solely dependent on material choice; it also stems from meticulous engineering and design principles. Their pumps are crafted with reinforced frames, thick liners, and well-balanced impellers to handle severe operations without structural failure. The company uses computational simulations to optimize flow paths, minimize mechanical stress, and reduce wear zones. These sophisticated design techniques improve the pump’s ability to sustain high-impact solids, fluctuating pressures, and chemical exposure without compromising its structural integrity. By focusing on robustness in design, CNSME ensures that their slurry pump manufacturer not only perform well but also retain their operational capability over years of intensive use, making them a wise investment for long-term operational resilience.

Precision Manufacturing and Strict Quality Control

Maximizing a pump’s service life also requires precision manufacturing and strict quality control processes. CNSME maintains high standards throughout every stage of production, from raw material inspection to final assembly. Every component undergoes rigorous testing to verify that it meets the company’s specifications for durability, dimensional accuracy, and performance. This thorough quality assurance process guarantees that each pump leaving the factory is free from manufacturing defects and is built to last. Additionally, CNSME continuously updates its manufacturing techniques to incorporate the latest advancements in machinery and quality standards, ensuring that the durability and consistency of their products remain unmatched in the industry.

Maintenance Strategies and Customer Support

CNSME understands that product longevity is also influenced by how well the pumps are maintained during their operational life. To assist customers in maximizing service life, the company provides comprehensive maintenance strategies, training, and technical support services. They offer detailed maintenance guidelines tailored for different operational conditions, helping clients perform timely inspections, wear part replacements, and adjustments to prevent early failure. Their global network of service technicians offers on-site support, ensuring that any issues are addressed promptly before they escalate into critical failures. CNSME’s proactive approach to maintenance support helps clients extend the operational life of their pumps significantly, ensuring consistent performance and protecting their initial investment over many years.

Pioneering R&D for Continuous Improvement

Innovation is at the heart of CNSME’s strategy to enhance service life. The company invests heavily in research and development to discover new materials, refine their design approaches, and incorporate cutting-edge technologies. They are exploring smart monitoring systems that predict wear and degradation, allowing operators to schedule maintenance precisely when needed. Their R&D efforts are also focused on developing more environmentally sustainable materials without compromising durability. By embracing new ideas and technological advancements, CNSME ensures its pumps remain at the forefront of durability and reliability, enabling industries to operate more efficiently and with greater confidence over extended service intervals.

Looking Forward: A Long-Term Vision for Industry Leadership

CNSME’s unwavering dedication to maximizing pump service life distinguishes it as a true leader in heavy-duty slurry handling solutions. The company’s future vision involves further innovation in materials science, smarter equipment integration, and comprehensive support systems that promote long-term operational stability. They aim to develop pumps that go beyond industry standards, providing clients with equipment that can endure the most extreme conditions with minimal maintenance. This long-term focus on service life not only benefits customers by reducing costs and downtime but also aligns with industry trends toward more sustainable and dependable industrial operations. CNSME’s ongoing commitment to durability cements its reputation as a manufacturer that genuinely cares about the longevity and reliability of its products, helping industries globally achieve safer, more efficient, and economically sound operations.