Patrocinados

Automotive Fuel Injection System Market Restraints Impacting Growth and Innovation

The automotive fuel injection system market has experienced significant growth due to increasing demand for fuel-efficient and low-emission vehicles. Fuel injection technology plays a critical role in optimizing engine performance and meeting stringent environmental regulations worldwide. However, despite its growth potential, the market faces several restraints that could impede its expansion and innovation. This article explores the key restraints affecting the automotive fuel injection system market and their implications for industry players and stakeholders.

High Cost of Advanced Fuel Injection Systems

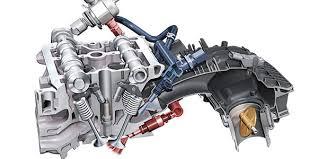

One of the primary restraints in the automotive fuel injection system market is the high cost associated with advanced fuel injection technologies. Systems such as Gasoline Direct Injection (GDI) and Common Rail Direct Injection (CRDI) involve complex components and precision manufacturing processes. The integration of electronic control units (ECUs), high-pressure pumps, and advanced sensors further adds to production costs.

These high costs translate to increased vehicle prices, which can limit adoption, especially in price-sensitive emerging markets. Automotive manufacturers often need to balance between incorporating advanced fuel injection systems and maintaining competitive vehicle pricing, which sometimes slows the deployment of cutting-edge technologies.

Stringent Emission Regulations and Compliance Challenges

While environmental regulations drive the demand for efficient fuel injection systems, they also pose significant compliance challenges. Different regions have varying emission standards, such as Euro 6 in Europe, BS VI in India, and Tier 3 in the United States. Meeting these diverse and frequently evolving regulations requires continuous product development and customization.

The need to develop fuel injection systems that can meet multiple regional standards increases R&D expenses and complicates manufacturing. Smaller players, in particular, struggle to keep up with these regulatory demands, limiting their ability to compete effectively.

Increasing Adoption of Electric Vehicles

The rapid growth of electric vehicles (EVs) presents a notable restraint to the fuel injection system market. As the automotive industry shifts toward electrification to reduce carbon emissions and dependency on fossil fuels, internal combustion engines (ICEs) face declining demand.

While fuel injection systems remain vital for ICEs and hybrid vehicles, the rising penetration of battery electric vehicles (BEVs) reduces the overall market size and growth opportunities for fuel injection manufacturers. This transition compels companies to diversify or adapt their portfolios, which can be resource-intensive.

Complex Supply Chain and Raw Material Dependence

Fuel injection systems rely on precision-engineered components, many of which require specialized materials such as high-grade alloys and electronic parts. The complex supply chain involved in sourcing these materials is vulnerable to disruptions caused by geopolitical tensions, trade restrictions, or natural disasters.

Moreover, fluctuations in raw material prices, such as metals used in injectors, directly impact manufacturing costs. Supply chain instability can delay production schedules and increase operational risks, posing challenges for companies aiming to maintain steady output and competitive pricing.

Technical Complexity and Maintenance Issues

Modern fuel injection systems have grown increasingly sophisticated, integrating electronic controls, sensors, and actuators to optimize fuel delivery. However, this technical complexity presents maintenance challenges for vehicle owners and service providers.

Diagnosing and repairing advanced fuel injection systems require specialized knowledge and equipment, which may not be readily available in all regions, especially in developing countries. High maintenance costs and limited technical support can deter customers, impacting aftermarket sales and brand loyalty.

Fuel Quality Variability in Emerging Markets

In many emerging economies, fuel quality remains inconsistent, with higher levels of impurities and varying octane ratings. This variability in fuel quality poses a significant restraint on the performance and durability of sophisticated fuel injection systems.

Contaminated or substandard fuels can cause injector clogging, corrosion, and inefficient combustion, leading to increased emissions and reduced engine life. Manufacturers must design robust systems capable of handling such fuel variability, which adds to development complexity and cost.

Slow Adoption of Aftermarket Upgrades

Although aftermarket fuel injection systems can improve engine performance and reduce emissions, their adoption remains relatively slow. Consumers often hesitate to invest in aftermarket upgrades due to cost concerns, lack of awareness, or trust in original equipment.

This restraint limits the growth of aftermarket fuel injection systems and restricts opportunities for manufacturers to expand revenue streams beyond OEM sales.

Competitive Pressure from Alternative Technologies

Fuel injection systems face competition not only from electrification but also from alternative fuel delivery technologies such as carburetors in niche markets or emerging technologies like direct cylinder injection and fuel cell systems.

While fuel injection currently dominates in modern ICE vehicles, technological shifts and innovation in alternative propulsion methods pose a restraint on long-term market growth, forcing manufacturers to continuously innovate and diversify.

Conclusion

The automotive fuel injection system market is poised for growth driven by the demand for efficient and cleaner vehicles. However, multiple restraints challenge the market’s expansion, including high costs, regulatory complexities, the rise of electric vehicles, supply chain vulnerabilities, and technical maintenance issues.

To navigate these challenges, manufacturers must invest in cost-effective innovation, adapt to diverse regulatory landscapes, and develop fuel injection systems that can tolerate varying fuel qualities. Additionally, exploring complementary markets such as hybrid vehicle components and aftermarket solutions will be crucial.

Understanding and addressing these restraints is essential for stakeholders aiming to sustain competitiveness and capitalize on future opportunities within the evolving automotive landscape.

Categorías

Read More

Esports, small pertaining to electric athletics, features converted coming from a area of interest subculture right world-wide happening, engaging followers worldwide which consists of cut-throat heart, qualified avid gamers, along with huge fanbase. On this page, many of us will certainly learn about the globe involving esports, looking at their beginning, progression, influence on...

Did you ever think about how some exporters always appear to know which markets to export their goods to? It is not a matter of probability or guesswork. Most successful companies employ an intelligent tool customs trade data to identify new export markets and expand quicker. Let's learn what customs trade data is, how it assists, and how you can employ it as well. ...