Patrocinado

Key Trends Shaping the Future of the Global Veneer Sheets Market

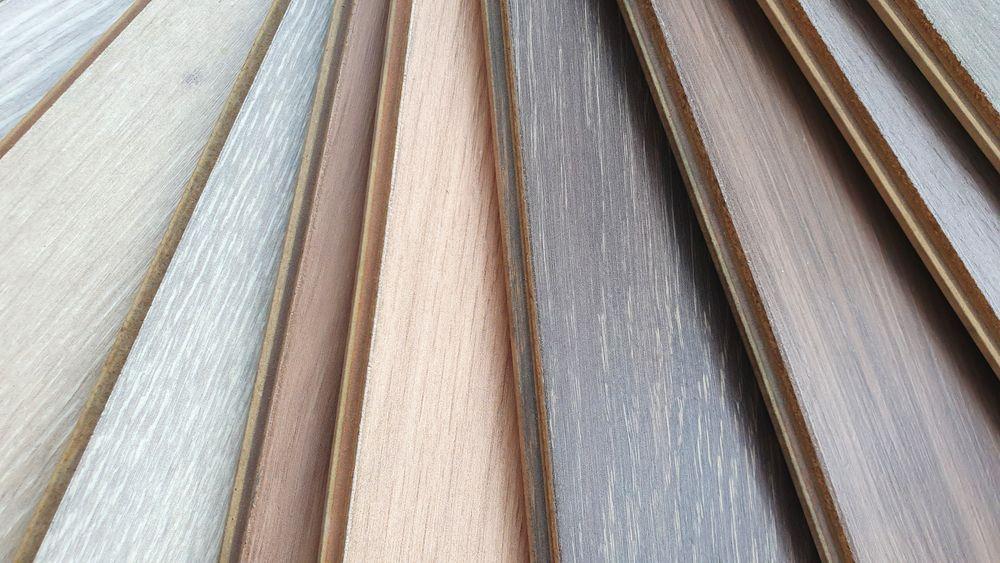

The veneer sheets market is a critical segment within the global wood-based materials industry, offering a cost-effective and sustainable alternative to solid wood for furniture manufacturing, interior decoration, and construction. Veneer sheets, which are thin layers of wood sliced from logs, provide the natural aesthetics and texture of solid wood while maximizing resource efficiency. The market dynamics of veneer sheets are complex and driven by an interplay of multiple factors including demand drivers, technological innovations, supply chain considerations, and evolving consumer preferences.

This article explores the key dynamics influencing the veneer sheets market and the implications for manufacturers, suppliers, and investors.

Demand Drivers

One of the primary market dynamics is the rising demand for veneer sheets, fueled by increasing urbanization, rising disposable incomes, and changing lifestyles. The growing middle-class population in emerging economies such as India, China, and Southeast Asia is investing more in home furnishing and renovations, thereby driving demand for affordable yet visually appealing wood products. Veneer sheets offer a perfect balance between cost and aesthetics, making them a preferred choice in these markets.

In developed regions like Europe and North America, demand is driven by a focus on premium quality furniture and sustainable construction materials. Increasing consumer awareness about environmental sustainability is encouraging manufacturers and end-users to opt for veneer sheets sourced from certified sustainable forests. Green building codes and eco-friendly certifications have become significant factors influencing procurement decisions, further propelling demand.

Technological Innovation

Advancements in technology play a vital role in shaping the veneer sheets market dynamics. Modern slicing, drying, and finishing techniques have improved product quality, consistency, and durability. Digital printing technology allows manufacturers to replicate exotic wood grains and intricate patterns on veneer sheets, expanding design possibilities without relying solely on rare wood species. This innovation enables customization and faster turnaround times, meeting growing consumer expectations for unique and personalized products.

Moreover, improvements in adhesives and surface coatings have enhanced the moisture resistance and wear durability of veneer sheets, extending their use into more demanding applications such as kitchen cabinets, flooring, and wall panels in humid environments.

Supply Chain and Raw Material Factors

Raw material availability remains a critical dynamic in the veneer sheets market. The supply of timber, especially exotic or slow-growing species, is limited and subject to environmental regulations and harvesting restrictions. Sustainable forestry initiatives and certifications such as FSC and PEFC have become essential to ensuring ethical sourcing, but they also introduce complexity and cost to the supply chain.

Fluctuations in timber prices due to geopolitical factors, transportation costs, and trade tariffs impact veneer sheet manufacturing costs. Manufacturers are increasingly exploring engineered veneers and alternative wood species to mitigate supply risks and maintain cost competitiveness.

Competitive Landscape and Market Structure

The veneer sheets market features a blend of large multinational corporations and regional manufacturers, resulting in a moderately fragmented competitive environment. Market players compete primarily on product quality, sustainability credentials, innovation capabilities, and price.

Leading manufacturers invest heavily in research and development to produce engineered veneers that replicate the appearance of rare woods with enhanced performance attributes. Strategic alliances with forestry management organizations help secure a steady supply of certified raw materials, which is a growing competitive advantage.

Emerging market players in Asia-Pacific leverage cost efficiencies and proximity to raw materials to capture significant market share, while companies in North America and Europe emphasize premium quality and certification compliance to serve discerning clientele.

Consumer Preferences and Market Trends

Consumer preferences are evolving and significantly influence veneer sheets market dynamics. There is a growing trend toward natural, eco-friendly, and customizable interior décor solutions. Minimalist design styles like Scandinavian and Japandi, which highlight light wood tones and clean lines, are increasing veneer popularity.

Additionally, the rising popularity of modular furniture and compact living spaces supports the demand for lightweight, durable veneer applications that provide visual warmth without the weight and expense of solid wood.

Challenges and Constraints

Despite promising growth, the veneer sheets market faces several challenges. Raw material price volatility and supply chain disruptions can lead to increased production costs and delays. The rising availability of alternative surface materials such as laminates, melamine, and PVC films presents competition, especially in price-sensitive markets.

Furthermore, the veneer manufacturing process requires skilled labor to ensure high-quality slicing, finishing, and application. Labor shortages in some regions may limit production capacity and affect product consistency.

Outlook and Strategic Implications

Understanding the dynamics of the veneer sheets market is essential for stakeholders to identify growth opportunities and mitigate risks. Sustainability remains a core theme, driving manufacturers to invest in certified wood sourcing and eco-friendly production techniques. Technological innovation will continue to open new design possibilities and improve product resilience, enabling expansion into new applications.