Patrocinado

Top Equipment Used in Underground Utility Trenching for Efficient Project Completion

Underground utility trenching is a foundational process in modern infrastructure development. Whether installing water pipes, electrical conduits, fiber optic cables, or gas lines, trenching forms the essential pathway for these utilities. The efficiency, safety, and quality of underground utility trenching projects depend heavily on the right equipment being used. Choosing the proper machinery not only accelerates project timelines but also reduces costs, minimizes environmental impact, and ensures worker safety.

In this article, we will explore the top equipment used in underground utility trenching, highlighting how each plays a crucial role in delivering efficient and reliable project outcomes.

1. Excavators

Excavators are among the most versatile and indispensable machines on any trenching site. These tracked or wheeled vehicles come equipped with a boom, stick, and bucket and are capable of digging trenches of varying depths and widths.

Why Excavators Are Essential for Underground Utility Trenching:

-

Versatility: Excavators can handle a range of soil conditions, from soft clay to compacted gravel.

-

Depth and Precision: With skilled operators, excavators can dig trenches to precise depths required for specific utilities.

-

Attachment Options: Various bucket types, trenching attachments, and even hydraulic breakers can be fitted, enhancing their ability to manage different trenching challenges.

-

Mobility: Wheeled models provide faster movement across the site, while tracked excavators offer superior stability on uneven terrain.

Excavators are typically the go-to equipment for initial trench excavation and are also useful for backfilling once the utilities are laid.

2. Trenchers

While excavators provide general excavation capability, trenchers are specialized machines designed explicitly for trench digging. There are two main types of trenchers used in underground utility trenching:

Chain Trenchers

These use a heavy-duty chain equipped with cutting teeth that rotate around a boom, similar to a giant chainsaw, slicing through soil and rock to create narrow trenches.

Wheel Trenchers

Wheel trenchers utilize a large toothed wheel that cuts into the ground, making them highly effective in tougher or rockier soils.

Advantages of Trenchers in Underground Utility Trenching:

-

Efficiency: Trenchers can dig narrow, deep trenches rapidly, often faster than traditional excavation methods.

-

Precision: Ideal for utilities that require narrow trenches, reducing the amount of soil displaced.

-

Lower Surface Disruption: Because they dig precise trenches, the impact on surrounding areas is minimized.

-

Consistent Width: This uniformity is crucial for laying certain pipes and cables that require exact bedding and spacing.

For projects with repetitive trench dimensions and consistent soil conditions, trenchers offer a cost-effective and time-saving solution.

3. Backhoes

Backhoes are another common sight on trenching sites, particularly in urban or confined areas where space is limited. These machines combine a front loader bucket with a rear digging arm, making them multi-functional.

Role of Backhoes in Underground Utility Trenching:

-

Compact and Maneuverable: Ideal for working in tight spaces where larger excavators can’t access.

-

Versatility: Can perform digging, loading, and backfilling without needing multiple machines.

-

Cost-Effective: Often more affordable to rent or operate for small to medium trenching jobs.

Though backhoes may not match the speed or precision of trenchers, their flexibility makes them a popular choice for smaller scale utility trenches.

4. Vibratory Plows

For shallow underground utility installations such as fiber optic cables or irrigation pipes, vibratory plows are often preferred. This machine uses a vibrating blade to slice through the ground while simultaneously pulling the utility line into the trench.

Benefits of Vibratory Plows in Underground Utility Trenching:

-

Minimal Surface Disruption: The narrow blade minimizes damage to surface landscaping or pavements.

-

Fast Installation: Combines trenching and utility placement in one continuous operation.

-

Cost Savings: Reduces the need for extensive backfilling and surface restoration.

Vibratory plows are best suited for soft soil conditions and shallow utilities but are invaluable for minimizing disruption in residential or environmentally sensitive areas.

5. Compactors and Rollers

After the utility has been installed, the trench must be backfilled and compacted to restore ground stability and prevent future settlement. Compactors and rollers are essential in this phase.

Why Compactors Matter in Underground Utility Trenching:

-

Ensuring Soil Stability: Proper compaction prevents the trench from collapsing and protects the utility line from damage.

-

Surface Restoration: Compacting the backfill supports surface pavements and landscaping.

-

Variety of Options: From handheld plate compactors to large ride-on rollers, equipment choices depend on trench size and site conditions.

Neglecting proper compaction can lead to costly repairs and safety hazards long after the project is complete.

6. Utility Locators and Ground-Penetrating Radar (GPR)

Though not excavation equipment per se, utility locators and GPR systems are vital for efficient and safe underground utility trenching.

How These Tools Support Trenching Operations:

-

Avoiding Existing Utilities: Locators detect existing underground cables, pipes, or conduits to prevent accidental strikes.

-

Surveying and Planning: GPR provides detailed imaging of subsurface conditions, helping crews plan trench routes effectively.

-

Reducing Risk: Accurate locating minimizes utility damage, project delays, and safety risks.

Integrating these technologies into trenching operations enhances efficiency by preventing costly mistakes and rework.

7. Water Trucks and Dust Control Equipment

On many trenching projects, controlling dust and stabilizing soil is a significant concern, especially in dry or windy environments.

Role in Underground Utility Trenching:

-

Dust Suppression: Water trucks spray down disturbed soil to reduce airborne dust hazards.

-

Soil Stabilization: Moisture improves soil cohesion during excavation and backfilling.

-

Improved Visibility and Safety: Reducing dust improves visibility for operators and nearby workers.

Though auxiliary, these machines contribute to a smoother workflow and safer work environment.

Conclusion

Efficient underground utility trenching requires a combination of specialized equipment tailored to the project’s size, soil conditions, utility types, and environmental constraints. Excavators, trenchers, backhoes, vibratory plows, and compaction equipment form the backbone of most trenching operations. Complementary technologies like utility locators and dust control equipment further enhance safety and productivity.

Categorias

Leia mais

Microsoft SC-300 Genuine Dumps - Most straightforward Test Readiness Methodology As of late, we have seen that numerous IT competitors need to get the Microsoft SC-300 Exam Dumps certificate. The significant explanation for the spike in Character and Access Director Partner SC-300 declaration request is that presumed organizations all over the planet lean toward Microsoft Personality and...

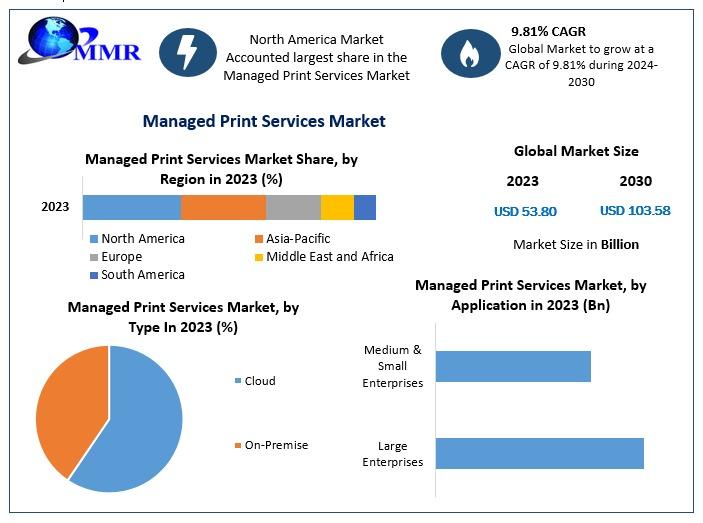

Managed Print Services Business Overview: The managed print services market is anticipated to grow at a compound annual growth rate (CAGR) of 9.81% to reach US$ 103.58 billion by 2030. Maximize Market Research, a renowned global market analysis firm, forecasts substantial growth for suppliers in the Managed Print Services market. Having worked with over 600 clients worldwide,...