Patrocinado

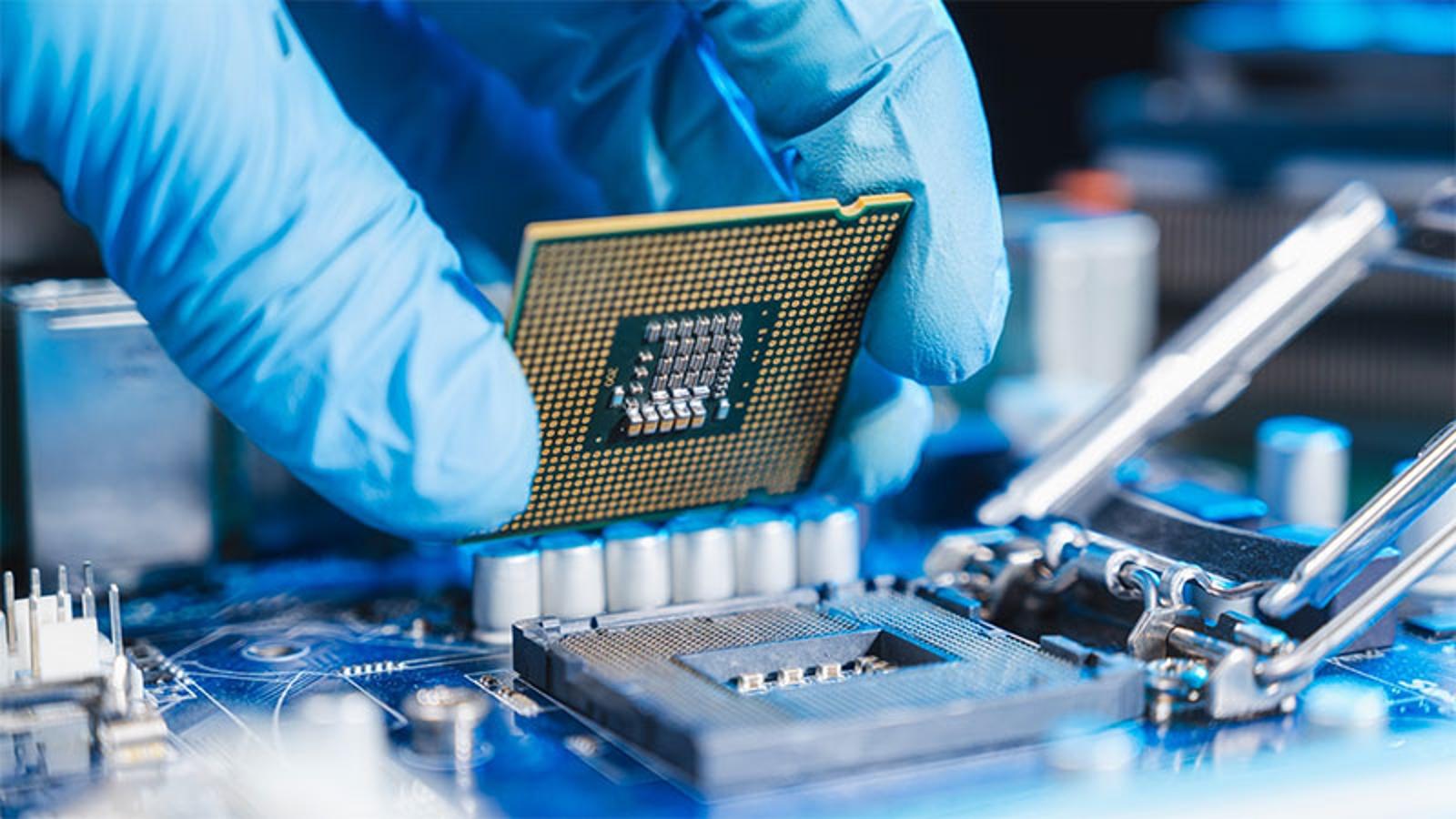

Semiconductor Assembly and Testing Services (SATS) Market Challenges Amid Rising Geopolitical Tensions and Supply Chain Disruptions

The semiconductor assembly and testing services (SATS) market is facing mounting challenges in an increasingly volatile global landscape. As demand for advanced semiconductor solutions continues to grow, numerous risks threaten the stability and expansion of this industry. From geopolitical tensions and supply chain disruptions to rising operational costs and cybersecurity threats, SATS providers must navigate an array of obstacles to sustain their market presence. Additionally, rapid technological shifts and the increasing complexity of semiconductor devices add further pressure on companies striving to remain competitive.

Geopolitical Tensions and Trade Restrictions

Escalating geopolitical tensions and trade restrictions pose significant threats to the SATS market. Many countries are tightening regulations on semiconductor exports, particularly in response to national security concerns. The ongoing trade war between major economies, including the United States and China, has resulted in stringent controls on semiconductor manufacturing and exports, limiting market access for SATS providers. Restrictions on the supply of critical materials and advanced chip technologies further complicate the industry’s global operations, forcing companies to reassess their supply chain strategies.

Supply Chain Disruptions and Material Shortages

The semiconductor industry remains highly vulnerable to supply chain disruptions caused by global crises, natural disasters, and logistical challenges. Shortages of essential raw materials, such as silicon wafers and rare earth elements, have led to production delays and increased costs. Additionally, dependence on a limited number of suppliers for semiconductor components creates bottlenecks that can significantly impact manufacturing timelines. Companies must find alternative sourcing strategies and invest in supply chain resilience to mitigate these risks.

Rising Costs and Talent Shortages

The cost of semiconductor production has been rising due to inflation, energy price hikes, and increasing labor costs. Additionally, the industry faces a severe talent shortage, particularly in skilled engineering and manufacturing roles. As semiconductor devices become more complex, the demand for highly specialized expertise in assembly, testing, and quality control continues to grow. However, the lack of a sufficient talent pool slows innovation and increases operational inefficiencies, making it challenging for SATS providers to maintain high production standards.

Cybersecurity Risks and Intellectual Property Theft

The digital transformation of the semiconductor industry has exposed it to heightened cybersecurity risks. SATS providers handle sensitive data, including proprietary chip designs and testing protocols, making them prime targets for cyberattacks. Intellectual property theft is a growing concern, particularly as companies expand operations into regions with weaker regulatory frameworks. Cyber threats such as ransomware, data breaches, and espionage can result in significant financial losses and reputational damage, making cybersecurity investments a critical priority for SATS firms.

Technological Shifts and Market Competition

The rapid evolution of semiconductor technologies, including advanced packaging and heterogeneous integration, presents both opportunities and challenges. Companies must continuously invest in research and development to stay ahead in an intensely competitive market. However, the high costs associated with technological advancements can be a barrier, especially for smaller SATS providers. Additionally, the rise of in-house semiconductor manufacturing by major technology companies reduces outsourcing demand, threatening the market share of third-party SATS providers.

Regulatory Compliance and Environmental Concerns

Stringent environmental regulations and sustainability initiatives are reshaping the SATS industry. Governments worldwide are imposing stricter guidelines on semiconductor manufacturing, including waste disposal, carbon emissions, and hazardous material handling. Compliance with these regulations requires significant investments in eco-friendly technologies and operational modifications, increasing overall costs. Companies failing to meet sustainability standards risk facing legal penalties and reputational damage, further impacting their market position.

Conclusion

The semiconductor assembly and testing services (SATS) market faces a complex and evolving threat landscape. From geopolitical tensions and supply chain disruptions to rising costs and cybersecurity risks, companies must adopt strategic measures to mitigate these challenges. Investing in technological innovation, strengthening supply chain resilience, enhancing cybersecurity protocols, and complying with regulatory requirements will be essential for long-term success. As the global demand for semiconductors grows, the ability to navigate these threats will determine the future trajectory of SATS providers.

Categorias

Leia Mais

Mrs Poindexter CBD Gummies - Everybody merits their greatest wellbeing, satisfaction, and well-being! In any case, that can be difficult to accomplish without the Mrs Poindexter CBD Gummies. These fantastic sticky colors contain probably the most grounded hemp CBDs to assist you with mending and simpler than any time in recent memory. Also, best of all, these new gummies taste path...

Die Welt des Online-Glücksspiels hat in der Schweiz in den letzten Jahren einen beispiellosen Aufschwung erlebt. Immer mehr Spieler wenden sich digitalen Plattformen zu, die nicht nur Komfort und Flexibilität bieten, sondern auch ein umfassendes Unterhaltungserlebnis versprechen. In diesem Zusammenhang gewinnt der Begriff "Online Casino" zunehmend an Bedeutung. Dabei geht es...