How Extend Lifespan Your Industrial Electronics Repair Expert

Understanding how to extend the lifespan of your industrial electronics repair is vital for any organization aiming to improve their bottom line. By following best practices for maintenance, troubleshooting, and professional repairs, businesses can maximize the life of their equipment, reduce operational risks, and avoid costly replacements. In this comprehensive guide, we’ll explore key strategies that will help you extend the lifespan of your industrial electronics.

Regular Maintenance and Inspections

The foundation of extending the lifespan of any piece of industrial equipment lies in regular maintenance. Electronics in an industrial setting operate under extreme conditions, including heat, humidity, dust, and vibration. These harsh environments can cause wear and tear, leading to performance degradation over time.

Scheduled Inspections

Setting up a routine inspection schedule ensures that issues are detected early before they lead to major failures. Regular inspections should include checking for any physical damage (such as frayed wires, rust, or loose connections), as well as assessing the system's overall performance. Technicians should look for signs of malfunctioning components and check for overheating, excessive noise, or unusual vibrations.

Cleaning and Dust Removal

Dust and debris are notorious for clogging and damaging electronic components. Cleaning the devices and their surroundings is an essential task that should be performed frequently. This involves removing dust, dirt, and grime from the internal parts of the equipment. Regular cleaning will ensure that electronics stay cool, preventing overheating, and reducing the wear on sensitive components. It is also advisable to keep electronics in dust-free enclosures or install air filters to reduce the impact of airborne particles.

Lubrication of Moving Parts

Some industrial electronics have moving parts, such as motors, gears, and fans. These components should be lubricated regularly to reduce friction and prevent wear. The correct lubrication can help these parts move more efficiently, thereby improving their lifespan and reducing the likelihood of breakdowns.

Proper Operating Conditions

The environmental conditions in which your industrial electronics operate have a direct impact on their lifespan. These systems are often exposed to extreme temperatures, humidity, and even corrosive substances. To extend their lifespan, ensure that the operating conditions are ideal.

Control Temperature and Humidity Levels

Electronics are sensitive to temperature fluctuations and excessive humidity. Overheating is one of the most common causes of electronic failure. It’s essential to maintain a stable temperature within the recommended operating range. Similarly, high humidity can cause condensation inside components, leading to corrosion. Use air conditioning, dehumidifiers, and temperature control systems to manage environmental conditions.

Use Surge Protection

Electrical surges and power spikes can cause significant damage to industrial electronics. Installing surge protectors or uninterruptible power supplies (UPS) can protect the equipment from sudden power surges. A surge protector helps to dissipate excess electrical energy, preventing it from reaching the components of your industrial electronics and causing damage.

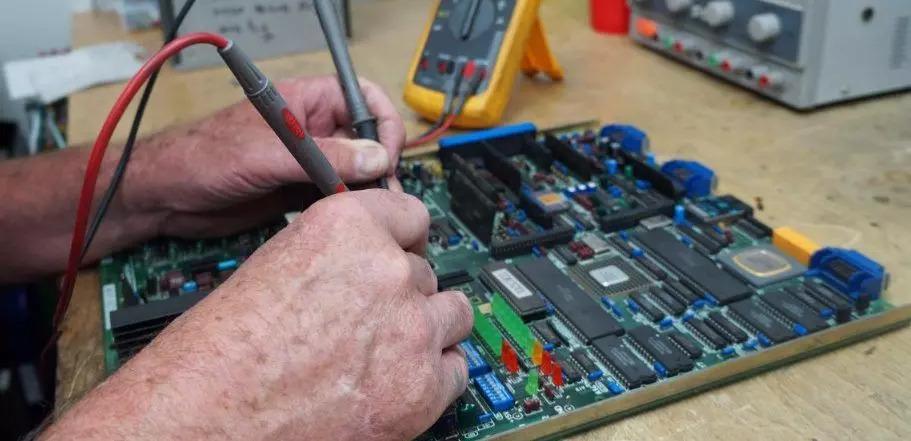

Professional Repair and Calibration

Even with regular maintenance and proper operating conditions, industrial electronics may encounter issues from time to time. When this happens, it is crucial to address the problems quickly and effectively. Professional repair services and calibration can help to restore equipment to its optimal condition and extend its useful life.

Address Issues Promptly

Delaying repairs or ignoring minor issues can lead to more significant problems in the future. If you notice any irregularities, such as unexpected shutdowns, unusual noises, or malfunctions, call in a qualified technician as soon as possible. Prompt attention to these issues will prevent minor glitches from evolving into catastrophic failures, saving you both time and money in the long run.

Calibration Services

Industrial electronics must be regularly calibrated to ensure that they continue to perform accurately and reliably. Calibration involves adjusting the equipment to meet the manufacturer’s specifications, ensuring that sensors and other electronic components are working correctly. Regular calibration is particularly important in industries where precision is critical, such as in manufacturing, robotics, and automation.

Upgrading and Replacing Components

Even with the best care and maintenance, there will come a time when some components need to be upgraded or replaced. By keeping up with technological advancements and replacing outdated parts, you can ensure that your industrial electronics remain efficient and reliable.

Use High-Quality Replacement Parts

When repairing or replacing components, always opt for high-quality parts that are designed for your specific electronics. Using substandard or generic parts may save money initially, but it can result in poor performance and premature failure. OEM (Original Equipment Manufacturer) parts are often the best choice because they are specifically designed for your equipment and meet the manufacturer’s performance standards.

Regular Software and Firmware Updates

In addition to hardware maintenance, software and firmware updates are essential for maintaining the performance of industrial electronics. Manufacturers often release updates to improve functionality, fix bugs, and address security vulnerabilities. Ensure that your devices are running the latest software versions to enhance performance and ensure continued reliability.

Training Your Workforce

Having a well-trained workforce is a critical factor in ensuring the longevity of industrial electronics. Proper operation and handling by employees can reduce the risk of unnecessary damage and wear. Implement training programs that teach employees about the equipment’s specific requirements, safe handling procedures, and how to perform basic troubleshooting.

Teach Troubleshooting Skills

Training employees to perform basic troubleshooting can prevent small issues from escalating. When workers can identify potential problems and make minor adjustments or repairs themselves, they can keep systems running smoothly without waiting for external support.

Safety Protocols

Safety training should also be a priority. This includes teaching employees about the proper safety protocols when working with industrial electronics, such as avoiding electrical hazards, handling sensitive equipment with care, and using proper protective gear.

Conclusion

Extending the lifespan of your industrial electronics repair is not just about maintaining equipment—it’s about adopting a holistic approach that includes regular maintenance, optimal operating conditions, professional repairs, and timely upgrades. By following these expert strategies, you can ensure that your industrial electronics continue to function efficiently, save costs on repairs and replacements, and reduce downtime in your operations.

Taking care of your industrial electronics ensures that your business can operate smoothly and profitably, avoiding unnecessary disruptions and safeguarding your long-term success.

Follow Us More Links:-

Follow Us On Facebook:- https://www.facebook.com/synchronics

Follow Us On Instagram:- https://www.instagram.com/synchronicselectronics/

Follow Us On Linkedin:- https://in.linkedin.com/company/synchronics

Follow Us On Twitter:- https://x.com/synchronics

Add:- 4th Floor, Lotus Enora, Opp. Rutu Villa Bunglows, 24 Mt. Main Road, New Alkapuri, Gotri, Vadodara 390 021, Gujarat (INDIA)

Call Us :- +91-704-308-4455 || +91-704-309-4455 || +91-265-400-1555 || +91-265-356-1183

Email Us:- email@synchronics.co.in

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness