Sponsored

Automotive 3D Printing: Revolutionizing the Future of Mobility

Categories

Read More

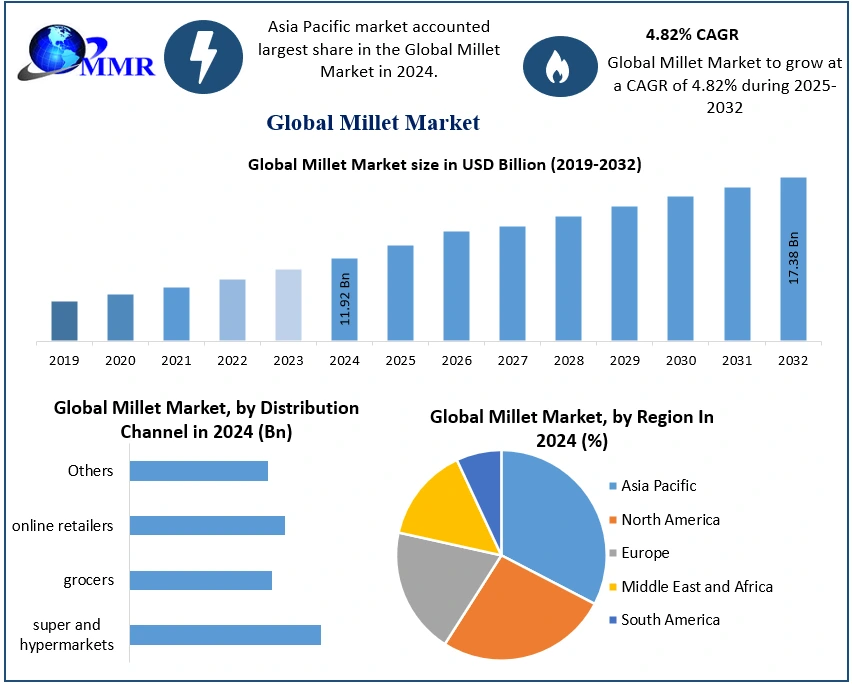

The Millet Industry is experiencing robust expansion, propelled by rising consumer demand for nutritious and climate-resilient grains, supportive government policies, and growing innovation across product categories. The millet market reached USD 11.92 billion in 2024 and is projected to grow at a compound annual growth rate (CAGR) of 4.82%, reaching...

The appeal of adventure beckons to those who seek the thrill of the unknown, and for many riders, the Royal Enfield Himalayan 450 is the vehicle of choice to answer that call. With its rugged design and legendary potentiality, the Himalayan 450 is built to conquer the most challenging terrains the world has to offer. However, to truly unlock its full potential and make every journey...