Enhancing Polymer Durability with Izod/Charpy Impact Testing

The resilience and durability of polymers are critical factors in numerous industries, from automotive to construction. To ensure the reliability of polymer materials, manufacturers rely on advanced testing methods like izod and charpy impact test. In this article, we delve into the significance of these tests and the role of Izod Impact Testers in enhancing polymer durability.

Understanding Polymer Strength

Polymer materials, including plastics and composites, serve diverse purposes due to their unique properties. However, their ability to withstand impacts and external forces varies based on factors such as molecular structure and processing techniques. Assessing the strength of polymers is crucial to guaranteeing product performance and safety.

Importance of Impact Testing

Impact testing simulates real-world scenarios where polymers may experience sudden forces or collisions. By subjecting materials to controlled impacts, manufacturers can evaluate their resistance to fracture and deformation. This data informs material selection, design optimization, and quality control processes, ultimately enhancing product reliability.

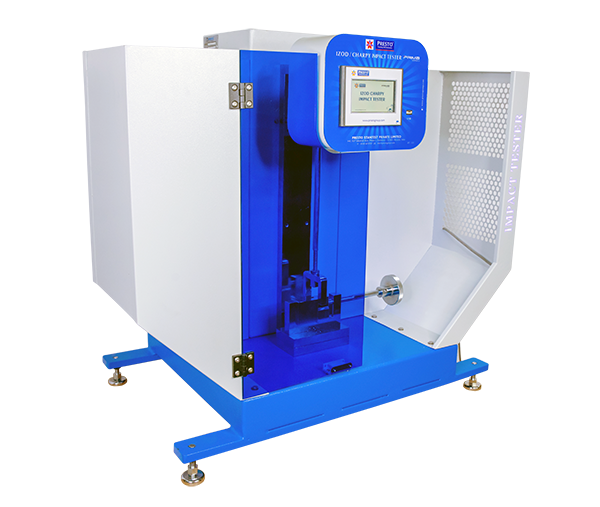

Exploring the Izod Impact Tester

The Izod Impact Tester is a specialized instrument designed for conducting impact tests on polymers. Named after its inventor, Edwin Gilbert Izod, this device measures the energy absorbed by a specimen during fracture. By quantifying this energy, engineers can assess the material's toughness and resilience.

Conducting Izod and Charpy Tests

Both Izod and Charpy tests evaluate a material's resistance to impact, but they differ in sample configuration and orientation. In Izod testing, a notched specimen is clamped vertically, while Charpy testing involves a notched specimen clamped horizontally. Despite these differences, both tests provide valuable insights into material performance.

Features of Modern Impact Testers

Modern Izod Impact Testers boast advanced features to streamline testing procedures and enhance accuracy. These may include adjustable hammer weights, digital displays for precise measurements, and automated safety mechanisms. Additionally, some models offer compatibility with various specimen sizes and shapes, catering to diverse testing needs.

Presto Group's Commitment to Quality

As a leading provider of testing equipment, Presto Group is dedicated to innovation and customer satisfaction. Their range of Izod Impact Testers exemplifies this commitment, offering reliability, accuracy, and user-friendly operation. With optional accessories and comprehensive support services, Presto Group ensures seamless testing solutions for polymer manufacturers worldwide.

Conclusion

In an ever-evolving industrial landscape, the demand for durable and reliable polymer materials continues to grow. Izod and Charpy impact testing serve as indispensable tools for evaluating material strength and performance. By investing in quality testing equipment like Izod Impact Testers, manufacturers can uphold the highest standards of product quality and safety.

Get Your Izod Impact Tester Today

Ready to enhance your polymer testing capabilities? Visit Presto Group's website to explore their range of izod impact tester and accessories. With industry-leading performance and unmatched reliability, these instruments are essential assets for any polymer manufacturing facility.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness