Sponsorizzato

Bonding Materials: The Glue That Holds the World Together

In the world of construction, manufacturing, and even in our everyday lives, bonding materials play a crucial role in holding things together. Whether it's building a skyscraper, assembling a smartphone, or simply fixing a broken vase, the right bonding materials are essential for ensuring stability, durability, and functionality. In this blog, we'll explore the fascinating world of bonding materials, their types, applications, and their significance in various industries.

What Are Bonding Materials?

Bonding materials, often referred to as adhesives or glues, are substances used to join two or more surfaces together. They work by forming a strong and durable connection between the materials, allowing them to function as a single unit. These materials come in various forms, including liquids, pastes, tapes, and even powders, each designed for specific applications.

Types of Bonding Materials

The world of bonding materials is incredibly diverse, with numerous types tailored to different needs and requirements. Some of the most common bonding materials include:

1. Epoxy Resin: Epoxy resin is a versatile bonding material known for its exceptional strength and durability. It's commonly used in construction, automotive, and aerospace industries for applications that require high structural integrity.

2. Cyanoacrylate (Super Glue): Super glue is a fast-bonding adhesive that forms a strong bond between surfaces almost instantly. It's ideal for small-scale repairs and DIY projects.

3. Polyurethane Adhesive: Polyurethane adhesives are known for their flexibility and resistance to moisture. They are often used in woodworking and for bonding materials with different coefficients of thermal expansion.

4. Silicone Sealant: Silicone sealants are excellent for creating watertight seals and are commonly used in bathrooms, kitchens, and in sealing windows and doors.

5. Construction Adhesives: These adhesives are designed for bonding building materials such as wood, metal, and concrete. They provide a strong and long-lasting bond, making them essential in construction projects.

6. Hot Melt Adhesives: Hot melt adhesives are solid at room temperature but melt when heated. They are widely used in packaging, woodworking, and product assembly.

7. Thermosetting Adhesives: These adhesives cure through a chemical reaction when exposed to heat. They are used in applications where high temperature resistance is required.

8. Pressure-Sensitive Adhesives: These adhesives require only slight pressure to form a bond and are commonly found in tape and label applications.

9. Natural Adhesives: Natural adhesives, such as animal glue and plant-based glues, have been used for centuries in crafts and woodworking.

Applications of Bonding Materials

The applications of bonding materials are incredibly diverse, and they are an integral part of various industries. Here are some common applications:

1. Construction: Bonding materials are used in building structures, from bonding concrete blocks to gluing insulation materials.

2. Aerospace: Aircraft and spacecraft rely on bonding materials for the assembly of critical components.

3. Automotive: Adhesives are used in vehicle assembly, reducing weight and improving fuel efficiency.

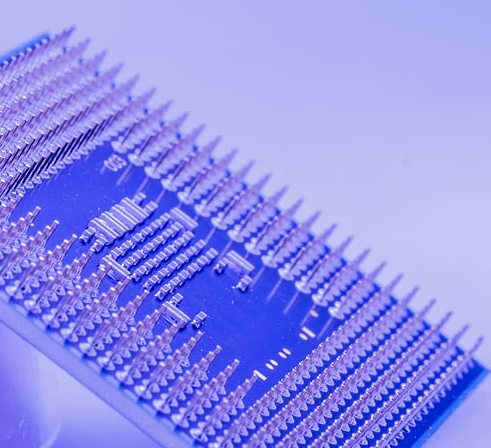

4. Electronics: The assembly of electronic devices, from smartphones to computers, relies on adhesives to secure components.

5. Medical: Adhesives are used in medical devices, wound care products, and even in surgeries.

6. Woodworking: Woodworkers use adhesives to join wood pieces in furniture and cabinetry.

7. Packaging: Adhesives are crucial in sealing packages and creating tamper-evident seals.

8. DIY and Home Repairs: Everyday repairs and DIY projects often involve the use of bonding materials like super glue or epoxy.

9. Textiles: The textile industry relies on adhesives for bonding fabrics and materials.

10. Footwear: Shoe manufacturing utilizes adhesives to bond soles, uppers, and various components.

Significance of Bonding Materials

The importance of bonding materials cannot be overstated, and here are some key reasons why they are indispensable:

1. Strength and Durability: Bonding materials can create bonds that are as strong or even stronger than the materials themselves. This is crucial in construction, aerospace, and automotive industries.

2. Weight Reduction: Adhesives allow for lightweight designs in aerospace and automotive engineering, contributing to fuel efficiency and performance.

3. Corrosion Resistance: Some bonding materials provide excellent resistance to corrosion, making them ideal for marine and outdoor applications.

4. Flexibility: Certain adhesives offer flexibility, allowing materials to expand and contract without compromising the bond. This is important in applications with temperature variations.

5. Sealing and Insulation: Bonding materials are used to create seals against water, air, and other environmental factors. They also provide insulation properties.

6. Efficiency: Adhesives often offer faster assembly times compared to traditional mechanical fastening methods.

Challenges and Innovations

While bonding materials have come a long way, there are still challenges in developing adhesives that meet ever-evolving industry requirements. Some of these challenges include:

1. Environmental Impact: Developing adhesives with reduced environmental impact is a growing concern. Innovations in bio-based and eco-friendly adhesives are on the rise.

2. Extreme Conditions: Industries such as aerospace and automotive require adhesives that can withstand extreme conditions, including high temperatures and pressures.

3. Nanotechnology: Nanotechnology is opening up new possibilities for adhesive technology, allowing for even stronger and more versatile bonds.

4. Advanced Composites: As materials like carbon fiber composites become more prevalent, the need for adhesives capable of bonding these advanced materials grows.

Conclusion

Bonding materials are the unsung heroes of the modern world, holding together the structures and products we rely on every day. From the towering skyscrapers that define our cities to the smartphones that connect us, bonding materials play a vital role in shaping our world. As technology advances and industries evolve, we can expect even more innovative bonding materials to emerge, further pushing the boundaries of what is possible in construction, manufacturing, and beyond. So the next time you pick up your smartphone or marvel at a stunning architectural masterpiece, remember the crucial role that bonding materials have played in bringing these creations to life.