Upgrade Your Comfort The Ultimate Blown In Insulation Machine Buying Guide

In the fast evolving world of construction and home improvement, the insulation revolution is in full swing. Blown in insulation machines have emerged as the go to solution for efficient, precise, and cost effective insulation projects. If you're ready to upgrade your comfort and join the insulation nation, this ultimate buying guide will navigate you through the key considerations when selecting the perfect blown in insulation machine.

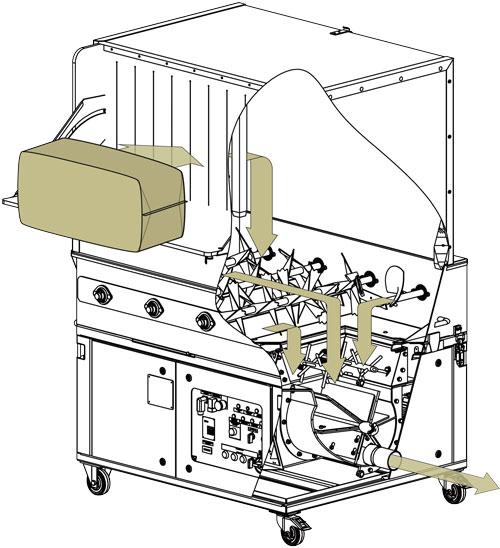

Understanding Blown In Insulation Machines

Before delving into the buying guide, lets recap what makes blown in insulation machines an indispensable tool in the construction and insulation industry.

Precision Application

Blown-in machines excel in providing precision application of insulation material. The technology allows for targeted delivery, ensuring uniform coverage and efficient insulation in various spaces, from attics to walls and beyond.

Efficiency and Speed

Efficiency is a hallmark of blown-in machines. The streamlined application process significantly reduces labor hours, making insulation projects more time-effective. This efficiency not only saves costs for contractors but also translates into quicker completion times for homeowners.

Versatility with Materials

Blown-in machines are versatile, accommodating various insulation materials such as fiberglass, cellulose, and mineral wool. This adaptability allows users to choose the material that best suits the specific requirements of the project, providing flexibility in insulation solutions.

The Ultimate Blown In Insulation Machine Buying Guide

Now, let's explore the essential factors to consider when selecting a blown-in insulation machine to ensure that you make a well-informed and strategic investment in your insulation endeavors.

Performance and Output

Consider the performance and output capacity of the machine. The right machine should align with the scale of your projects. For larger projects, opt for a high-output machine that can handle a substantial volume of insulation material, ensuring efficiency and timely project completion.

Material Compatibility

Different insulation materials have varying densities and characteristics. Ensure that the machine you choose is compatible with the specific material you intend to use. A versatile machine that can accommodate a range of materials provides flexibility for future projects.

Portability and Maneuverability

Evaluate the portability and maneuverability of the machine, especially if you anticipate working in tight or hard-to-reach spaces. Look for features such as sturdy wheels, a compact design, and adjustable handles that enhance the machine's ease of transport and operation.

Power Source

Consider the power source of the machine. Blown-in insulation machines are available in electric and gas-powered models. Electric machines are suitable for indoor use, while gas-powered machines offer the advantage of mobility for outdoor projects. Choose the power source that aligns with the nature of your insulation projects.

Hose Length and Control

The length of the hose plays a crucial role in determining the reach and coverage of the insulation material. Select a machine with a hose length that suits the dimensions of your projects. Additionally, opt for a machine with responsive and user-friendly controls, allowing you to adjust settings easily during operation.

Maintenance and Durability

Inspect the maintenance requirements and durability of the machine. A machine with easy maintenance features, such as accessible components and straightforward cleaning procedures, will contribute to its longevity. Investing in a durable machine ensures reliability and minimizes downtime due to repairs.

Remote Control Options

Consider models with remote control options for added convenience. Remote controls enable operators to make adjustments to the machine settings without needing to be in direct proximity. This feature is particularly valuable in scenarios where precise control is essential or when working in challenging spaces.

Manufacturer Reputation and Support

Research the reputation of the manufacturer. Choose a reputable brand with a track record of producing reliable and high-performance blown-in insulation machines. Additionally, assess the availability of customer support, including technical assistance, replacement parts, and warranty coverage.

Budget Considerations

While quality is paramount, it's essential to align your purchase with your budget. Evaluate the cost of the machine against its features, performance, and expected return on investment. A balance between affordability and functionality ensures that you make a strategic and cost-effective purchase.

User Reviews and Testimonials

Before finalizing your decision, explore user reviews and testimonials for the specific blown-in insulation machine you are considering. Real-world experiences from other users provide valuable insights into the machine's performance, reliability, and overall user satisfaction.

Advancing Comfort with the Right Blown In Insulation Machine

In conclusion, upgrading your comfort through blown in insulation machine begins with selecting the right machine for your projects. By considering factors such as performance, material compatibility, portability, and user reviews, you can make an informed decision that aligns with your insulation goals. As a key player in the insulation nation, investing in a quality blown in insulation machine is not just a purchase its a strategic step towards efficient, precise, and cost effective insulation solutions. Elevate your projects, streamline your workflow, and advance comfort with the ultimate blown-in insulation machine that meets your specific needs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness