Are you interested in laser cutting but don't know where to start? Look no further! We have just the thing for you - Free DXF File. These files make it easy for anyone, regardless of experience level, to get started with laser cutting. In this blog post, we'll explain what DXF is and why it's so beneficial. Plus, we'll share some tips on how to use these files effectively and confidently. So buckle up and get ready to take your creativity to new heights with free DXF files!

What is DXF?

DXF stands for Drawing Exchange Format. It is a file format that was developed by Autodesk, the creators of AutoCAD software. The DXF File Free Download format is commonly used in the field of engineering and design to exchange data between different CAD (Computer-Aided Design) programs.

In essence, DXF files are vector-based graphics that contain information about shapes, lines and curves. They are compatible with most laser cutting machines and can be easily modified using various computer programs.

One great advantage of using DXF files for laser cutting is their flexibility - they can be scaled up or down without losing quality or resolution. This makes it easy to adjust designs to suit different project requirements.

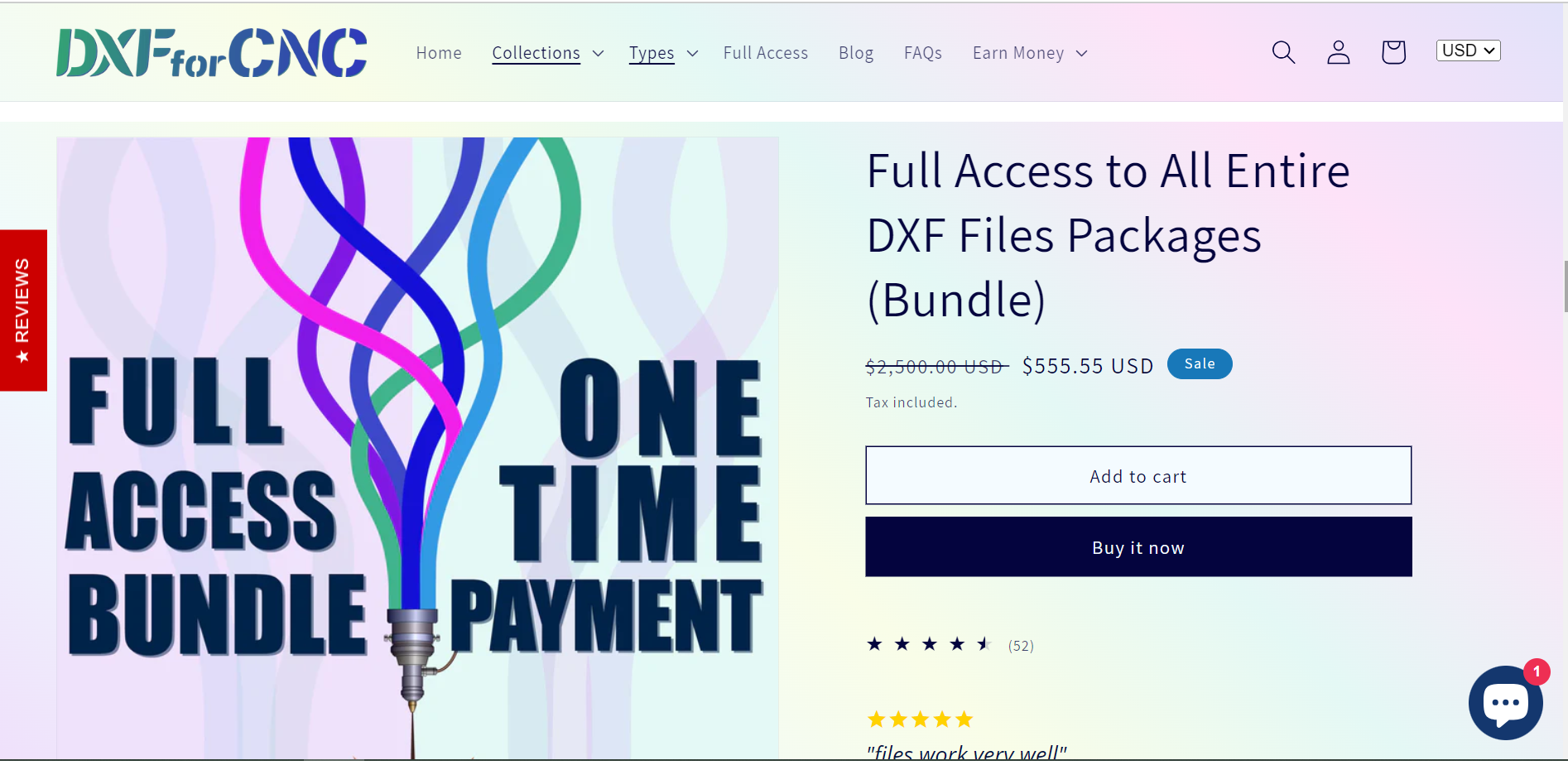

Another benefit of using DXF files is their universality - there are many websites where you can download free DXF files online, making them accessible to anyone interested in getting started with laser cutting.

If you're looking to get into laser cutting but don't have experience with CAD software or designing your own projects from scratch, then using pre-made DXF files could be the perfect solution for you!

How to use DXF Files

DXF files are a popular file format for laser cutting, CNC machining, and other computer-aided manufacturing processes. However, if you're new to using DXF files, it can be challenging to know how to use them effectively.

The first step is to obtain the DXF file from a reliable source. You can find free DXF files online or purchase them from a reputable provider. Once you have your file downloaded onto your computer, you will need software that supports the format.

There are many software options available that support DXF files, such as AutoCAD and Adobe Illustrator. These programs allow users to open and manipulate the design within the file easily. Users can modify elements of the design or create their own designs by adding new shapes or lines.

After opening up your desired software program and importing your chosen DXF file, make sure that all of its layers are visible before exporting it in preparation for laser cutting. Ensure everything is accurate with regards to measurements so that there aren't any issues when transferring it over into an actual physical item made through laser cutting technology.

Understanding how to use DXF Files takes time but once mastered; they become an invaluable tool for producing precise cuts and intricate designs in various materials quickly!

What are the benefits of using DXF Files?

DXF (Drawing Exchange Format) files are essential for laser cutting enthusiasts. They offer unparalleled versatility and convenience when designing and executing intricate designs on various materials.

One of the most significant benefits of using DXF Files is their compatibility with almost all CAD software. This means that you can create your design in different programs, save it as a DXF file format, and import it into your laser cutter's program without any hassle or loss of quality.

Additionally, DXF Files allow you to customize your designs according to your preferences since they contain all the necessary information about shapes, lines, curves, etc., making them easy to manipulate regardless of size or complexity.

Another advantage of using DXF files is their precision. The file format stores data in vector form rather than pixels, which ensures accurate cutting results every time. This eliminates common issues like jagged edges or misaligned cuts that could affect the overall quality of the project.

Utilizing this file format saves time during setup and execution while ensuring high-quality results that meet industry standards.

How to start laser cutting with confidence today

Laser cutting may seem intimidating, but with the right tools and knowledge, anyone can start creating amazing projects. Here are some tips for starting laser cutting with confidence today:

Make sure you have a good understanding of your laser cutter's capabilities and limitations. This will help you avoid any potential mistakes or accidents.

Next, select a DXF file that suits your project needs. Take into account the material you will be using and ensure that the design is compatible with your machine.

Before starting to cut, always do a test run on scrap material to ensure everything is functioning properly. This way, if there are any issues or adjustments needed, they can be made without wasting expensive materials.

When it comes time to actually cut out your design, take it slow and steady. Don't rush through the process as this could lead to errors or damage to both your machine and project.

Once you've completed your first successful laser cutting project don’t stop there! Keep practicing and experimenting with new designs so that you can continue building upon what you've learned.

With these tips in mind, anyone can confidently begin their journey into the world of laser cutting!

Tips for laser cutting with DXF files

When it comes to laser cutting with DXF files, there are a few tips that can help you achieve the best results possible. First and foremost, make sure your file is properly formatted and scaled correctly before sending it to the laser cutter. This will ensure that your design is cut precisely as intended.

Another important tip is to choose the appropriate power and speed settings for your particular material. Different materials require different settings in order to achieve clean cuts without burning or melting.

It's also a good idea to test your design on scrap material before cutting into the final piece. This allows you to make any necessary adjustments or corrections without wasting valuable materials.

Additionally, be mindful of any intricate details or sharp corners in your design. These areas may require slower speeds or multiple passes in order to avoid charring or distortion.

Always take proper safety precautions when operating a laser cutter. Wear protective eyewear and never leave the machine unattended while in use.

By following these tips, you can confidently create beautiful designs using DXF files and laser cutting technology.

Conclusion

To sum up, DXF files are an excellent option for those looking to start laser cutting with confidence. They offer a wide range of benefits such as easy compatibility across different software programs, precise and accurate cuts, and the ability to customize designs according to your preferences.

By following the tips mentioned above, you can ensure that you create high-quality laser cut designs that meet all your requirements. So go ahead and explore the world of DXF files – it's free and full of endless possibilities!

Whether you're a seasoned professional or just getting started with laser cutting, DXF files are definitely worth considering. With their simple yet powerful features, they provide an accessible way for anyone to bring their creative ideas to life.

So what are you waiting for? Start exploring today!